We've established partnerships with globally renowned brands, further solidifying our reputation as a trusted leader in the industry.

Common Systems

Company Introduction

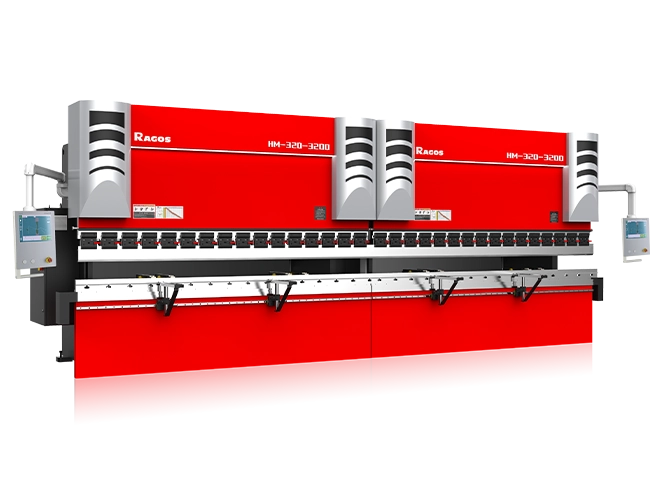

Jiangsu RAGOS, also known as JS RAGOS, is the manufacturing base of the RAGOS Group located in Jiangsu, China. Established in 2011, our company has grown into a global supplier of advanced metalworking machinery and automation solutions.

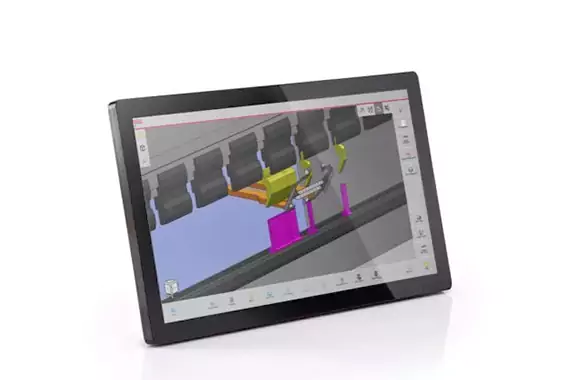

Application Client

Our partnerships with renowned global brands further solidify our reputation as a trusted leader in the industry.

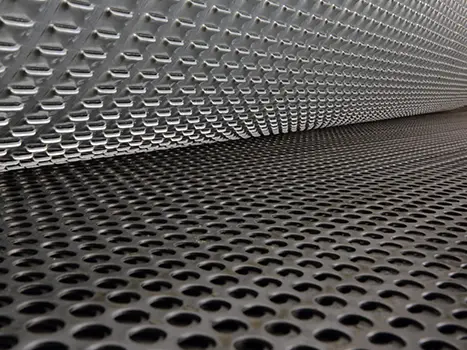

A Metal Fabrication Equipment Industry Leader

Whether you have a complex, low-volume metal cutting or steel fabrication project or one that requires a highly automated, high-speed process, RAGOS has you covered.