Press Brake 4-Axis CNC Back gauge With X, R, Z1, Z2 -Axis Diagram

1. High-Precision Motion Components

Equipped with ball screws and linear guides on the X and R axes for smooth, accurate positioning.

2. Precision Belts and YYC Rack Drive

The Z1–Z2 axes use precision belts and YYC rack-and-pinion systems for reliable and synchronized motion.

3. Advanced Finger Stops

Each finger features dual stops with micrometric adjustment, allowing fine positioning of parts with exceptional accuracy.

4. Mechanical Accuracy

Overall system accuracy of ±0.03 mm, ensuring consistent bending results.

5. High-Speed Movement

- Z1–Z2 axis speed: up to 1000 mm/s

- X axis speed: up to 500 mm/s

6. Load Capacity

Each support can safely handle workpieces up to 30 kg.

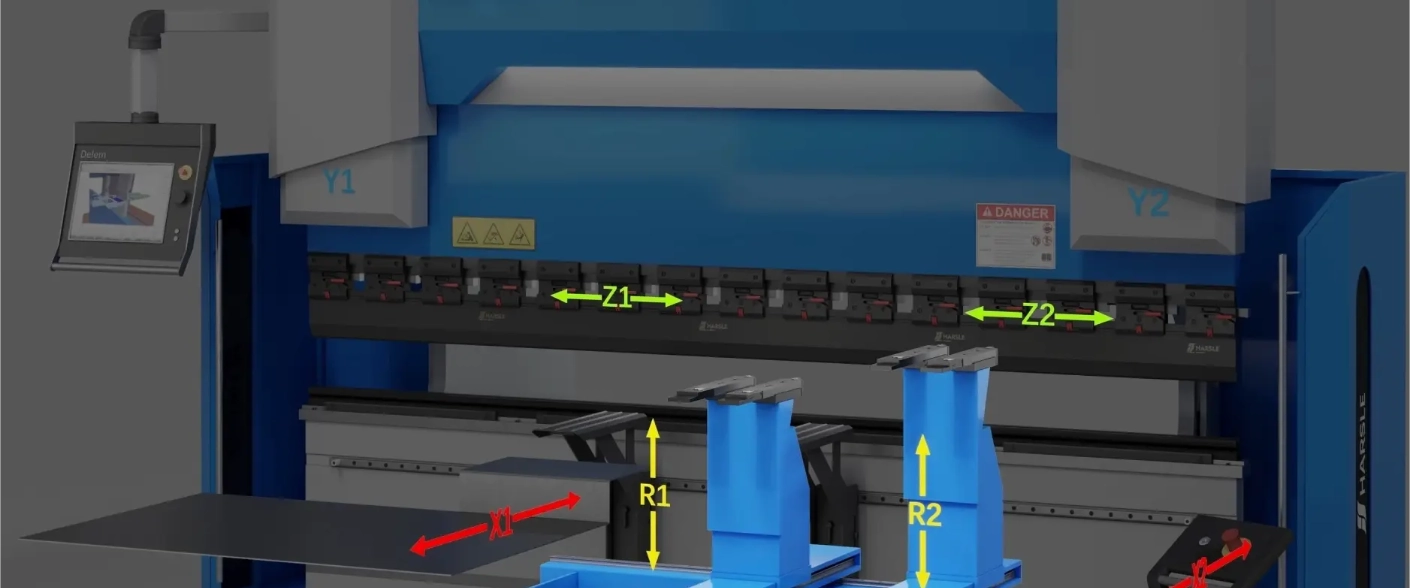

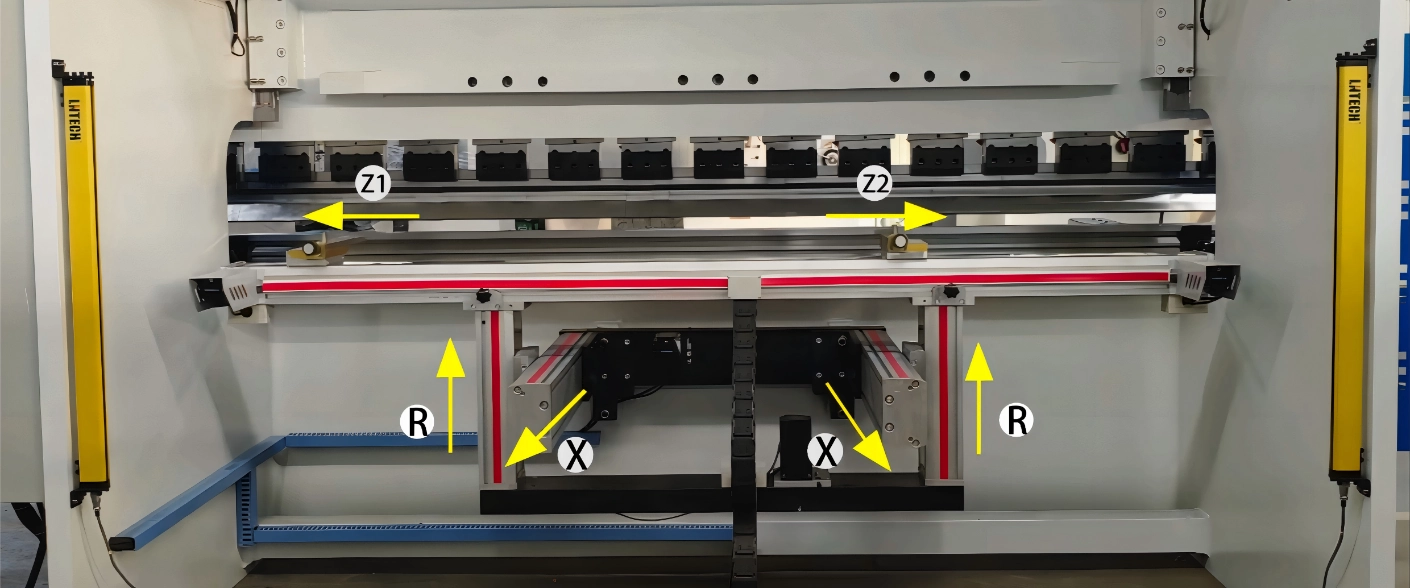

Press Brake 6-Axis CNC BackGauge With X1, X2, R1, R2, Z1, Z2-Axis

- X-Axis – Backgauge Position (Depth Control)

Controls the front–back movement of the backgauge fingers.

Determines how far the sheet metal is inserted into the machine before bending — thus defining flange length. - Y-Axis – Ram Movement

Controls the vertical movement of the ram (upper beam).

The Y1 and Y2 axes (left and right cylinders) determine bending depth and parallelism, ensuring accurate angles. - Z-Axis – Backgauge Finger Movement (Lateral Position)

Controls the left–right movement of the backgauge fingers (Z1 and Z2).

Allows positioning of the sheet for multiple bends at different locations along its length. - R-Axis – Gauge Height Adjustment

Controls the up–down movement of the backgauge fingers.

Used to support parts of different heights or perform step bending operations. - V-Axis (Crowning System)

Controls table or die compensation to counteract deflection during bending.

Ensures consistent angle and accuracy across the entire bending length, especially for long parts.

Solution for tandem press brakes

The PCSS–A embedded safety controller range expands the possibilities for machine control with the next generation solution for tandem press brakes. The latest tandem solution comprises a Tandem Adaptor that synchronises safety functions and control across both machines and a dedicated optical system for flexible guarding in both single and tandem configurations.