Delem Profile-S

Office press brake functionality

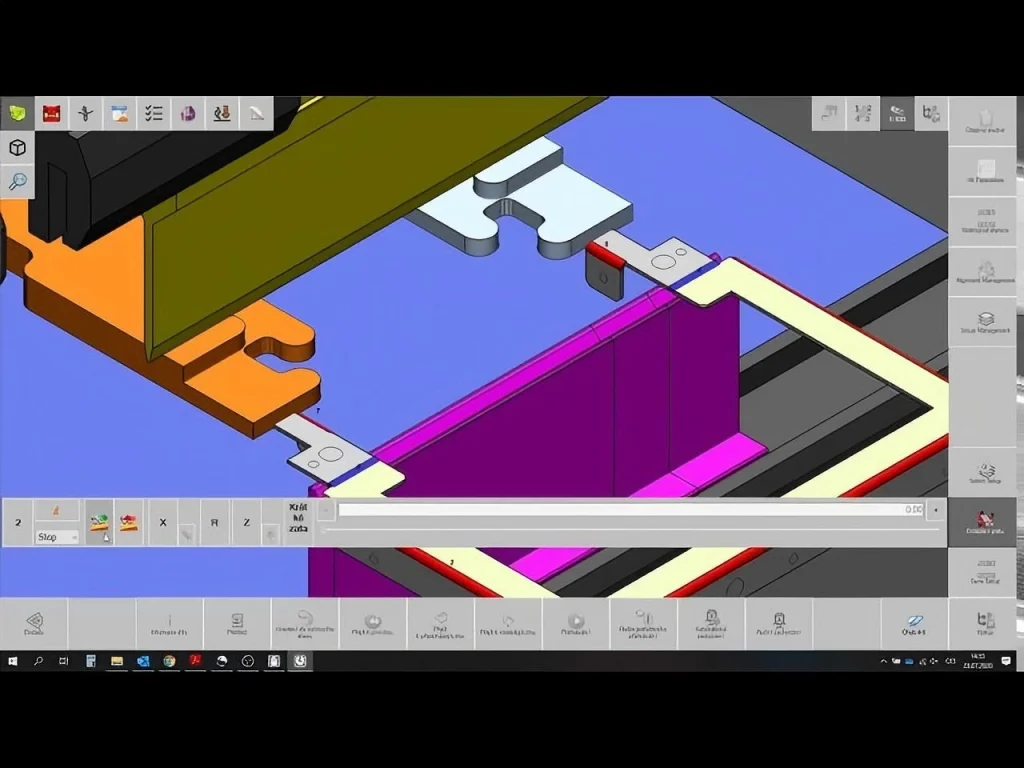

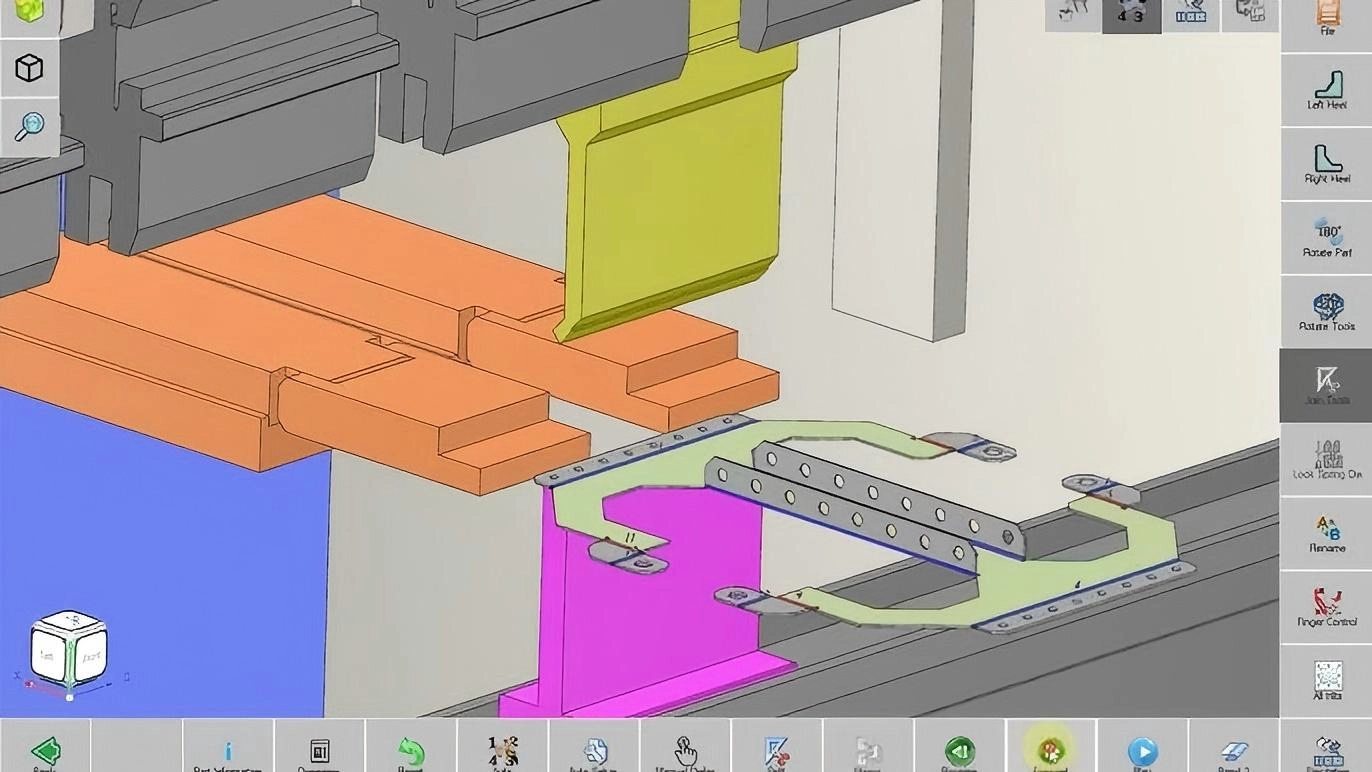

DA-Offline software maximizes machine efficiency and production output of press brakes. The Profile-S software facilitates offline programming and simulation the bending process. Production preparation, feasibility studies and tooling verification can be carried out offline.

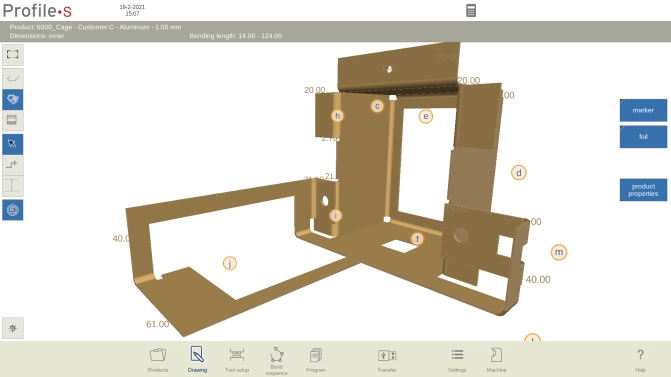

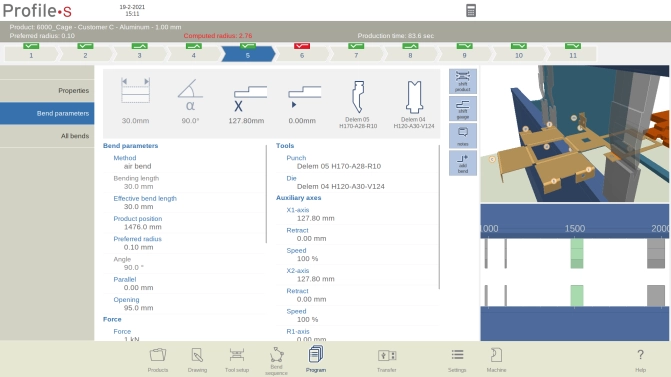

The Profile-S software offers advanced programming in 2D / 3D in line with the DA-60S controller software. The steps from the start of programming to the desired program including its transfer to the control are clearly embedded in the user interface. Programming the product graphically shows a true scale representation of the intended product. Realistic product visualization gives feedback on feasibility, collisions, required tools and tool adapters for production.

The CAD import functionality of Profile-S3D offers both DXF import as well as 3D CAD (Step/iges) product import. These interfaces use generic 3D-model file formats to make the software blend in as a part of the production chain, optimizing the production preparation process. Profile-S2D offers 2D-DXF tool import, making tool programming easier as ever.

Features

- Full scale offline programming

- Graphical product programming and bend sequence generation

- Feasibility studies and production preparation

- 2D/3D automatic bend sequence calculation

- Collision detection

- Product sharing over Windows networking with press brake CNC

- Machine setup preparation including print functionality

- Production time calculation

- DXF tool and product import

- 3D CAD product import

Production configuration

Standard

- 2D or 3D programming version

- 3D machine representation

- X1-X2 angle programming

- 3D finger view

- DA-60S familiar user interface

- DXF import function for products and tools (dies, punches, adapters)

- 3D CAD import function (Profile-s3D only)

Options:

- -Profile-S2D

- 2D offline programming software

- -Profile-S3D

- 3D offline programming software-Additional licenses for all versions

ESABEND 3D-M

Features and functionality based on processing:

Shears

- Management of sheet metal shear machines.

- Intuitive interface for machine control (from 1 to 3 axes).

- Interpolated management of inclination axes, blade gap, back gauge register, and evacuator.

Press Brakes (Conventional, Syncro, Hybrid, Electric, Tandem, Multi-Tandem)

- Dedicated HMI.

- Complete range of software for press brake machines.

- Simple and intuitive 2D and 3D interface, available both on-machine and offline, ensuring the best bending experience.

- Supports from traditional press brakes to complex multi-tandem systems.

- Integrated PLC combined with an open software structure allows flexible architecture design for complex systems — no need for third-party electronic devices.

- Management of Y1–Y2 axes, combined with rear back-gauge axes.

- Complete database for most sheet sizes and thicknesses.

- Automatic optimization of the bending sequence.

- Integration with various crowning systems (mechanical, hydraulic, hybrid) with real-time control.

- Interface with major pump and valve suppliers (Bosch, Rexroth, Hoerbiger, Voith).

- Interface with major bending angle measurement systems (Data M, Lazer Safe) for real-time monitoring.

- Interface with main PLC safety systems (Nuova Elettronica, Lazer Safe, Fiessler, Pilz).

- Easy robot integration, compatible with both anthropomorphic and Cartesian types.

- “Ready-to-use” software for hybrid machine applications, available as a full hardware + software package.

- “Ready-to-use” software for major types of electric presses (direct drive, pulley-belt, motor + gearbox), also available as a full hardware + software package.

Profile / Pipe Bending

- Management of major configurations of profile and pipe bending machines.

- Dedicated HMI.

- Double independent adjustment with orbital or linear trajectories.

- Electric or hydraulic roller management.

- Interpolation between electric axes for profile and coil creation.

- 2D view of the profile to be bent.

Roll Bending (Tubes)

- Management of main configurations for roll bending machines.

- Supports 3-roller and 4-roller setups.

- Dedicated HMI.

- Integration with sheet followers, towers, and interlocking axes such as loading and unloading robots.

- Expandable material database, customizable by the customer.

- Management of on/off or proportional valves.