Best CNC Press Brake Machine | High-Precision Sheet Bending Solutions

Best CNC Press Braze Machine: Accuracy and Workforce Productivity

A best CNC press brake machine is not merely a machine; it is the foundation of the current sheet metal fabrication. These machines have been tailored to the high-performance industrial needs, where precision, automation, and robustness are needed, and workshops and factories can respond to the demands of steel, aluminum, and electrical panel production that are high.

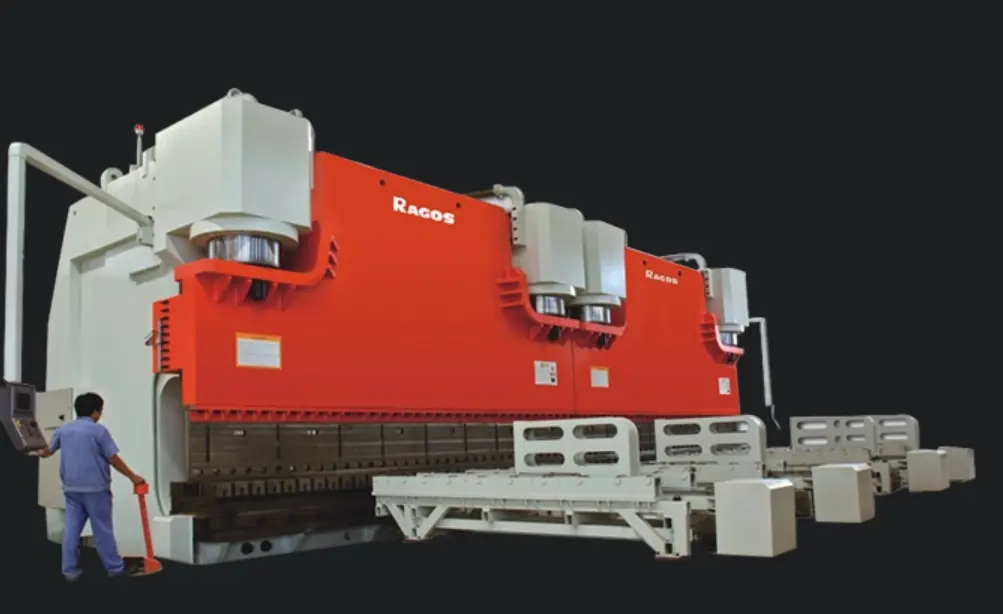

Buyers of the finest CNC press brake machine, or those wanting to modernize their plant with the latest and precision bending equipment, the JS Ragos heavy-duty press brake line has incomparable efficiency, flexibility, and safety.

Investigate Heavy Duty Press Brake

High Design Arch to the Utmost Accuracy

The CNC press brake is a high-performance machine that provides the highest level of bending and long-life performance. Its strong frame system provides stability to its structure, and any repetitive and high-quality bending can be done through its precision CNC control system, even in large-scale processes of industries.

The main technical characteristics are:

- CNC control on the press brake with multi-axis control ability to position and bend precisely.

- CNC bending system with adaptive bending technology is a servo-hydraulic type.

- Closed-loop bending control to ensure consistent results in production runs.

- Backgauge control to control the exact position of sheet metal.

- +-0.1 ° bending accuracy of sheet metal forming.

These characteristics make the machine ideal for industrial bending, sheet metal fabrication, and electrical panel production, which makes it the best CNC sheet metal press brake in the market.

Automation and Power Conservation

The JS Ragos heavy-duty press brake combines CNC plate feeding systems, which are automatic in transporting the metal sheets to the bending section. This minimizes manual handling, augments throughput, and minimizes production errors.

The DSVP (Double Servo Valve Pump) system, which is also available, can save a lot of energy by saving up to 70 percent of power and still provides high bending accuracy. Key advantages include:

High Precision: Dual servo motors provide high precision.

Saving Energy: Compared to the traditional hydraulic systems, it is efficient.

Low Noise: Minimal noise operation that would be applicable in contemporary workplaces.

Solidarity: A reduced number of hydraulic parts results in reduced failure.

Vario Adjustable Die System of Flexible Productions

The system Vario die in the JS Ragos press brakes enables flexibility in production, which means that the system can be used to make various thicknesses of sheet metal and bending angles. Features include:

- The 1000 mm (39.37") segments can be standard, with the length of beds between 1 and 12 m.

- Movement adjustment of individual segments of various V-opening sizes.

- Pneumatic gear system to change the V-size quickly in 5 seconds.

- Hardened rollers, which lower the bending force by 25-30 making it more efficient.

This renders the precision CNC bending machine very versatile, suited for the production of custom cabinets or the fabrication of controlled panels in industries.

Cooling of the Industry to Operate 24/7

In the case of heavy-duty CNC press brake machines, it is of great importance to provide a constant temperature of the hydraulic oil and servo motors. The industrial cooling unit ascertains:

- Stable bending performance

- Long-term reliability

- Inherent working in hot weather or 24-hour production.

- High accuracy of operations in industrial sheet metal fabrication workshops is facilitated by this cooling system.

Advanced Programmable CNC Controller

JS Ragos provides customizable CNC control systems which include Delem, Cybelec, ESA, and STEP, with 4-axis to 8-axis. Highlights include:

- Complex bending operations 2D/3D programming.

- Easy programming, graphical bending sequence editor.

- CNC programming offline to decrease downtime.

- Multi-step and completely automated compatibility.

This smart control unit guarantees the ideal CNC press brake machine to provide accurate and repeatable bending of any sheet metal task.

DSP Laser Light Curtain Operator Safety

Modern CNC hydraulic press brake machines are concerned with safety. The DSP laser protection system helps to identify items in the danger zone, which directly stops machine movement to avoid accidents. Features include:

- Synchronized protection zone with moving parts.

- Fast identification of roadblocks like operator hands.

- Connection with the CNC system of the machine to operate safely.

This, with industrial CNC sheet metal press brakes, can reach high standards of safety without lowering productivity.

Crowning Table to True Bends

A crowding table helps to counterbalance frame deflection caused during the bending process so that the angle of bending throughout the length of the sheet metal is constant. This mechanical or hydraulic adjustment ensures repeatability even in large-scale bending operations.

- Bends sheets of different lengths uniformly.

- Improves quality, minimizes waste on materials.

- Supports the accuracy of CNC bending machine use in industrial workrooms.

Tooling Service: Customizing

JS Ragos offers specialized tooling that is composed of 42CrMo high-strength alloy steel:

- Toughened to reduce heat losses.

- Flexible and faster tooling segments.

- Usable in Wila and Amada as well as other conventional tooling systems.

This facilitates easy handling of complex bending jobs and tailor-made sheet metal jobs, and ensures a consistent quality of work.

Laser Check Angle Measurement System

The Laser Check Angle Measurement System provides a highly accurate bending process, making automatic corrections to the angle and spring back compensation. Key benefits:

- Accuracy exceeding +-0.1deg

- Automatic correction and measurement of any type of material.

- Maximizes applied force on optimal bends.

A high-precision CNC press brake is supported by this system as the most suitable one in terms of industrial and electrical panel making.

Industrial Applications

The ideal CNC press brake machine, which is offered by JS Ragos, is applicable in various industries:

- Steel and aluminum sheet metal fabrication.

- Production of electrical panels and control cabinets.

- Manufacturing factories and workhouses.

- Manufacturing of heavy-duty goods that have to be bent on multiple axes.

It is a versatile CNC bending tool that ensures precision in demanding setting made it unique.

Why is JS Ragos CNC Press Brades a Good Choice?

The best CNC press brake machine will guarantee:

- Bending with a precision of +-0.1deg.

- DSVP technology that is energy efficient in operation.

- Variable production requirements: flexible tooling and V-die.

- Fully automatic systems plate feeds.

- DSP laser and light curtain system operator safety.

In industrial control panels, custom metal cabinets, and heavy-duty production, JS Ragos provides trustworthy and accurate CNC bending machines.

Conclusion

We provide press brake CNC control systems that can be fully customized, with axis configurations ranging from 4-axis to 6-axis and 8-axis. Every system is customized to meet the unique production needs of the client, whether they are standard bending, complex multi-step operations, or fully automated bending production. Our products are made to be as accurate, effective, and simple to use as possible.