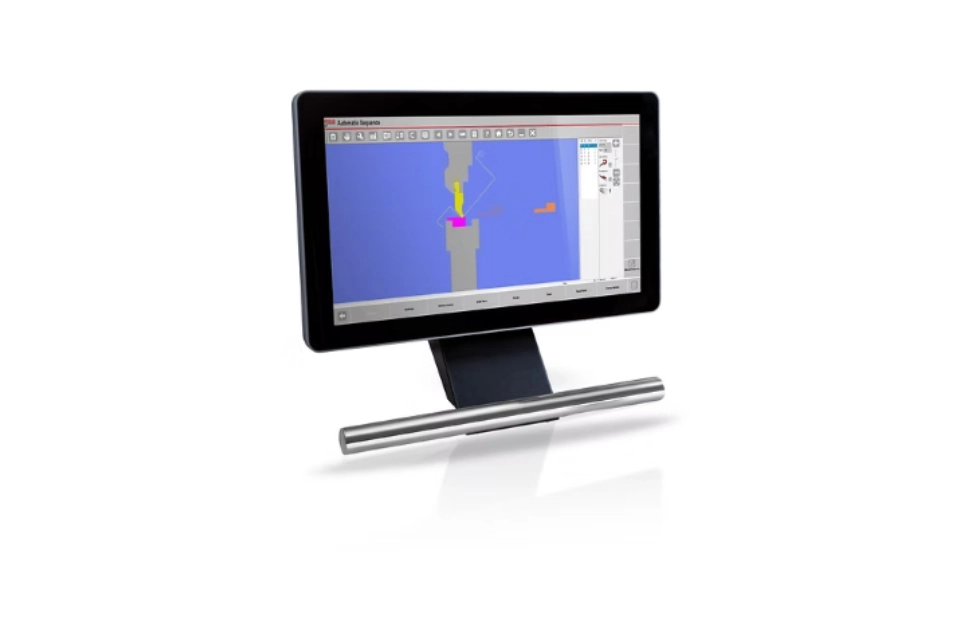

Delem DA-69T

Features

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-T3D offline software

Delem DD-60S

- 24-inch high-resolution color TFT display

- Provides bright, sharp visuals with excellent color accuracy.

- Industrial-grade touch functionality

- Ensures reliable, responsive operation even in demanding workshop environments.

- HDMI connectivity

- Allows seamless connection to external video sources or CNC systems.

- Proprietary CNC switch function

- Enables automatic input switching directly controlled from the CNC interface.

USB and peripheral connectivity

Includes multiple USB ports —

- • 2 automatically switched USB ports

- • 1 USB port that switches with the video source

- • 1 direct-access USB port for convenience

Delem DA69S

Control and Programming Features

- 3D & 2D Graphical Touch Programming

Intuitive touch-based interface for creating and editing bending programs in both 2D and 3D modes. - Real-time 3D Visualization

Full 3D simulation and machine representation during both programming and production phases. - 24-inch High-Resolution Color TFT Display

Delivers sharp graphics and clear visualization for complex bending operations. - Delem Modusys Compatibility

Supports modular scalability and system adaptability for extended control capabilities. - Comprehensive Connectivity

Includes USB and peripheral interfaces for data transfer and device integration. - Customizable User Applications

Allows user-defined applications to run within the controller’s multitasking environment. - Sensor Bending & Automatic Correction Interface

Real-time feedback and correction for enhanced bending precision. - Profile-S3D Offline Software

Enables offline programming and simulation for improved productivity and reduced setup time.

Delem DA53Tx

Control and Programming System

- Numerical Touch-Screen Programming

Easy-to-use graphical interface for fast and intuitive bending setup. - 15-inch High-Resolution Color TFT Display

Provides clear visibility and precise control over all process parameters. - Crowning Control

Ensures consistent bending angle along the full working length by compensating for frame deflection. - Servo and Frequency Inverter Control

Offers smooth, accurate, and energy-efficient ram movement. - Advanced Y-Axis Algorithms

Supports both closed-loop and open-loop valve control, providing exceptional precision and stability. - USB and Peripheral Connectivity

Simplifies data transfer, backup, and integration with external devices. - Profile-T Offline Software

Enables offline programming, simulation, and process optimization to maximize productivity.

Cybelec CT12PS

- Automatic Bend Function Calculations

- The control automatically calculates bend parameters such as force, angle, and crowning based on material and tooling data.

- Programmable Bending Sequences

- Complete bending programs and sequences can be stored, recalled, and edited for repeat production.

- Integrated Angle, Pressure, and Crowning Management

- Ensures consistent bending quality and accuracy across the entire length of the workpiece.

- Easy Manual Operation

- Allows simple and precise manual axis movement for setup or single bends.

- Offline 2D Programming Software Available

- Supports offline program creation and simulation to increase efficiency and reduce machine downtime.

Cybelec CT15PS

- Cybelec 15" Touch Screen Control Features

- Modern 15-inch Glass Touch Screen

Sleek, durable glass surface designed for industrial use — fully operable even while wearing gloves. - User-Friendly HMI Interface

Intuitive programming environment with dedicated setup wizards and auto-tuning functions for quick configuration. - 2D Graphical Profile Programming

Create and edit bending profiles directly on the screen with Touch Profile — enabling accurate 2D program creation. - Automatic Bending Sequence Calculation

The system automatically determines the optimal bending order for speed and precision. - EasyBend Mode

Simplified page for quick single bends and on-the-fly adjustments during production. - Large Storage Capacity

Ample memory for saving programs, tools, and materials for multiple projects. - Internal Backup & Restore Functions

Built-in data protection to easily recover settings or programs when needed. - Wireless Connectivity

Enables remote diagnostics, updates, and data exchange via laptop or network connection.

Cybelec VisiTouch Pac (VP88)

19" Advanced CNC Control System

- 19-inch Modern Glass Touch Screen

Sleek, industrial-grade design with a durable glass surface — fully operable even when wearing gloves. - User-Friendly HMI Interface

Intuitive programming environment designed for fast setup and efficient workflow. - 2D Profile and 3D Visualization

Real-time 2D programming and 3D simulation for complete control and precision. - Automatic Bending Sequence Calculation

The system automatically generates optimal bending sequences for maximum productivity. - Full Kinematics Support

Compatible with advanced axis configurations, including:

– X, X-relative, X-slave, R, R-slave, and Z axes

– Back and front multi-axis gauges

– Bending aids and lifting devices - Tandem Operation Support

Enables synchronized control of two press brakes for long or complex parts. - Tool Management and Import

Simplifies tooling setup with direct import and grouping functions for complex production. - Pre-Bend / Final Bend Control

Dedicated functions for precise adjustment of preliminary and final bending stages. - Hemming and Angle Measurement

Integrated tools for hemming operations and real-time angle verification. - Barcode Reader Integration

Supports barcode scanning for fast job identification and workflow automation. - Customizable, Industry 4.0 Ready

Open architecture allows customization and connectivity for smart manufacturing environments. - Windows-Based Platform

Runs on Windows 10 for multitasking and networking, with Windows 11 available on request.

ESA S840

Features:

- 15,6'' Touch Screen

- Up to 6 Axes

- ETS Real time Operating System

- Ethercat/CANopen or Analog Axes Interface

ESA S850

Features:

- 19'' Multitouch Screen

- Up to 156 Axes

- Windows 10 Operating System

- Ethercat/CANopen or Analog Axes Interface

ESA S860

Features:

- 19'' Multitouch Screen

- Up to 156 Axes

- Windows 10 Operating System

- Ethercat/CANopen or Analog Axes Interface

ESA S850

Features:

- 21'' Multitouch Screen

- Up to 156 Axes

- Windows 10 Operating System

- Ethercat/CANopen or Analog Axes Interface