CNC Press Brake for Control Cabinet | Machine for Electrical Panels

CNC Press Brake: Accuracy and Quality in Sheet Metal Bending

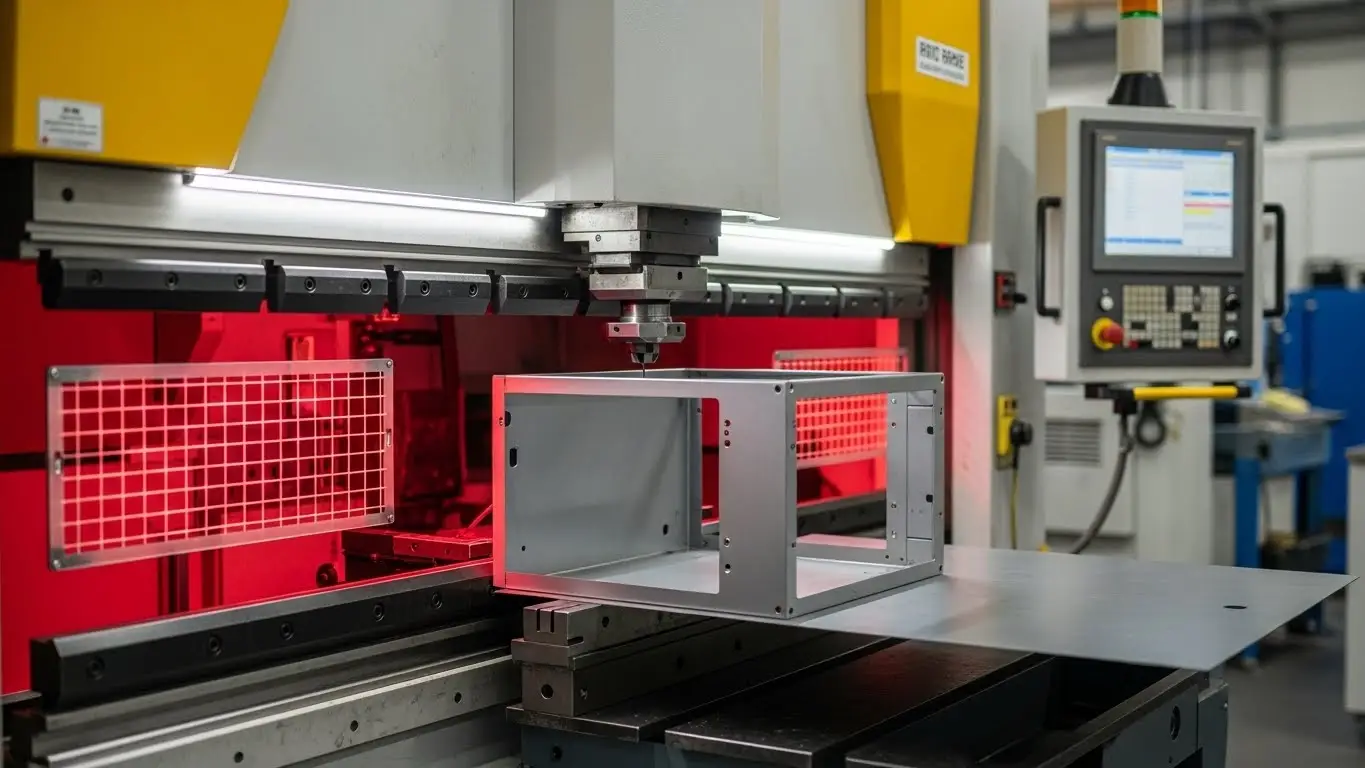

The CNC press braze control cabinet is a breakthrough technology in the fabrication of sheet metals in industrial applications, which will be produced to the highest levels of accuracy, longevity, and automation. As the demand for control panel manufacturing and electrical cabinets keeps growing, CNC press brake of electrical cabinets guarantees unmatched efficiency, consistency, and versatility. The machine is perfect in the workshop and factory that specializes in making quality cabinets to be used in industries and for electrical purposes.

Redesign of Press Brake CNC Control Cabinets

The industrial control panel CNC press brake has a strong frame design and is designed to support the heavy-duty workload, yet it has structural integrity. Its multi-axis CNC press brake system provides a high degree of control when it comes to the bending angles, the backgauge location, and synchronization between all its axes, and is applicable in small-scale workshops and production lines.

Key highlights include:

- Welded frame of high-strength and stress-relief heat treatment to reduce deformation.

- Surface finish shot blasted to improve rigidity and durability.

- The surfaces are machined to a high degree of precision using a CNC in order to ensure parallelism and perpendicularity, necessary to produce consistent bends.

The CNC sheet metal press brake cabinet has applications between electrical enclosures, machining, and control cabinet production, and has excellent repeatability and bend accuracy.

Accuracy and Precision with the Multi-Axis CNC System

The unique characteristic of the CNC press brake control cabinet fabrication is a multi-axis CNC control system. The machine incorporates sophisticated servo-hydraulic and backgauge controls to provide accuracy in bending sheet metal enclosures. The main technical characteristics are:

- Real-time control of bending angle with adaptive control against material variations.

- Enclosure closed-loop bending, which gives the results of a consistent bend.

- Simulation of bending sequences before production by graphical 2D/3D programming.

- Bending down-offline programming to minimize downtime and maximize efficiency.

- An error compensation system to ensure +-0.03 mm accuracy in complicated operations.

Such features make the CNC press brake of electrical enclosures ideal in high-precision scenarios, including steel and aluminum cabinet construction.

Backgauge System of High Precision

The CNC bending press control panel is fitted with the latest state of the art backgauge system, used to position sheet metal fast, accurately, and repeatably. Features include:

- Exact positioning of the finger using micrometric adjustment to the best.

- Movement of high speed through X, R, and Z axes.

- Single-layer support system to support lightweight materials.

- Designed to be used as a multi-axis bending machine.

This is an electrical enclosure precision-bending machine that guarantees smooth running, reliability, and better quality in the industrial control panels.

User-Friendly CNC Interface

The touchscreen CNC controller has been used in cabinet bending, where operators have an easy time programming the machine through the advanced software and graphical user interfaces:

- Control panels simulation of complex bends with 2D/3D graphical programming.

- Step-by-step-programming step-by-step bending sequence editor.

- CNC press brake software integration of industrial cabinets, which provides data transfer and connection to other production systems.

- A multitasking environment that is user-specific to manage custom bending applications effectively.

This interface gives both skilled operators and novices the ability to make high-quality bends with a short setup time and therefore increases overall productivity.

Protection of the Operator and the Safety

The contemporary CNC sheet metal press brakes are very crucial as regards safety in enclosures. The CNC press brake control cabinet controller is fitted with several protection systems:

- A laser or light curtain guard is used to avoid accidents when one is in operation.

- Punch prevention tools to fix punches when setting up tools.

- Safe and efficient handling of machines by means of ergonomic controls.

These not only guarantee the safety of operators but also minimize the risk of material damage to ensure a high output quality and consistency.

Industrial Cabinets High-Strength Tooling

The CNC bending machine that drives the control panels has high-quality tooling, which consists of 42CrMo steel, which will last longer and keep the accuracy of bending. Additional tooling characteristics are:

- Segmented tooling to allow flexible setup, with varying bending length and shape.

- Support Accessibility to Wila, Amada, and other standard tool systems so that they can be installed easily and changes are quick.

- Punches and die exposed to heat to increase their durability when used in heavy-duty activities.

This machine has been used in industrial control, fabrication of cabinets, and sheet metal panel bending due to the combination of precision tooling and CNC control.

Industrial Applications

The CNC press braze control cabinet is used in some industrial fields:

- Automation and control system electrical cabinet manufacturing.

- Fabrication of industrial control panels, such as steel and aluminum enclosures.

- Accurate sheet metal bending of machinery and industrial equipment.

- The need to have consistent, dependable bending performance in heavy-duty fabrication workshops.

The features of this machine enable it to be a flexible CNC bending solution for the needs of small-scale and industrial operations.

Comparison of CNC Press Brake Choices

In comparing alternatives like CNC press brake and hydraulic press to control cabinets, the CNC one provides:

- Increased repeatability and bending accuracy.

- Adaptive bending hydraulic control with servo-assistance.

- Large-scale production is ready to be automated.

- Complex panel programming, Graphical 2D/3D.

These are the benefits that make the CNC press brake in the fabrication of electrical enclosures superior in addressing the needs of the modern industry.

Conclusion

The CNC press brake control cabinet is a high-precision, versatile, and efficient solution to sheet metal fabrication. This control panel CNC bending press ensures accuracy, reliability, and productivity in industrial control panels, as well as in custom electrical enclosures. The CNC press braze of the control panels of JS Ragos is the best option in the case a business intends to upgrade its control cabinet manufacturing processes.