MSD⚙️ Mechanical Crowning vs Hydraulic Crowning in Press Brakes — Understanding the Difference

By JS RAGOS Machinery

Achieving accurate and consistent bending results is one of the key challenges in press brake operation. During bending, both the upper beam (ram) and lower table naturally deflect under high pressure, causing the center of the workpiece to bend differently from the edges.

To correct this, a crowning system is used to compensate for deflection — ensuring straight, consistent angles along the entire bending length.

There are two main types of crowning systems used today: Mechanical Crowning and Hydraulic Crowning. Both serve the same purpose, but their structures, working principles, and benefits differ.

🔩Mechanical Crowning

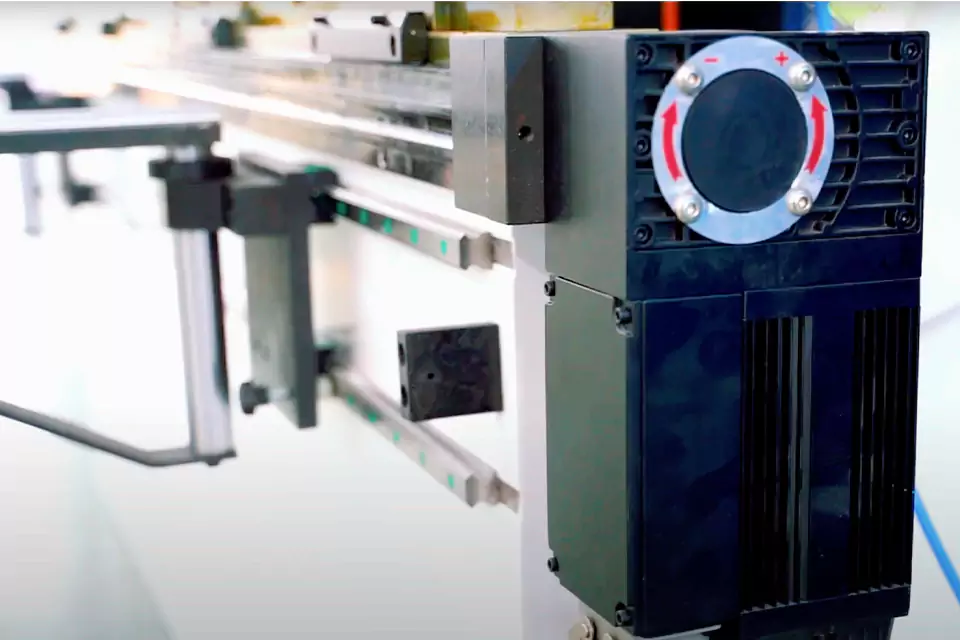

Mechanical crowning uses a series of precision wedges or cams installed beneath the press brake table. When adjusted, these wedges push upward in the middle to counteract the machine’s natural deflection during bending.

How It Works:

- The system consists of multiple wedge blocks or a motorized cam mechanism.

- The operator or CNC motor adjusts the wedges, slightly raising the table center.

- Once calibrated, the mechanical system maintains consistent compensation for repetitive work.

Advantages:

- Simple, robust structure with long service life.

- Lower cost and minimal maintenance.

- Perfect for medium tonnage and standard production needs.

JS RAGOS Exclusive Feature – Dual Compensation Technology:

At JS RAGOS, our mechanical crowning system features a “dual compensation” design.

After motorized adjustment, operators can fine-tune the compensation manually through small precision holes on the crowning table.

This unique two-way system allows micro-adjustment of bending angles for ultra-high accuracy — even on challenging materials or varying sheet thicknesses.

Limitations:

- Adjustment is preset rather than dynamic.

- Angle consistency may vary slightly for different materials or thicknesses.

💧 Hydraulic Crowning

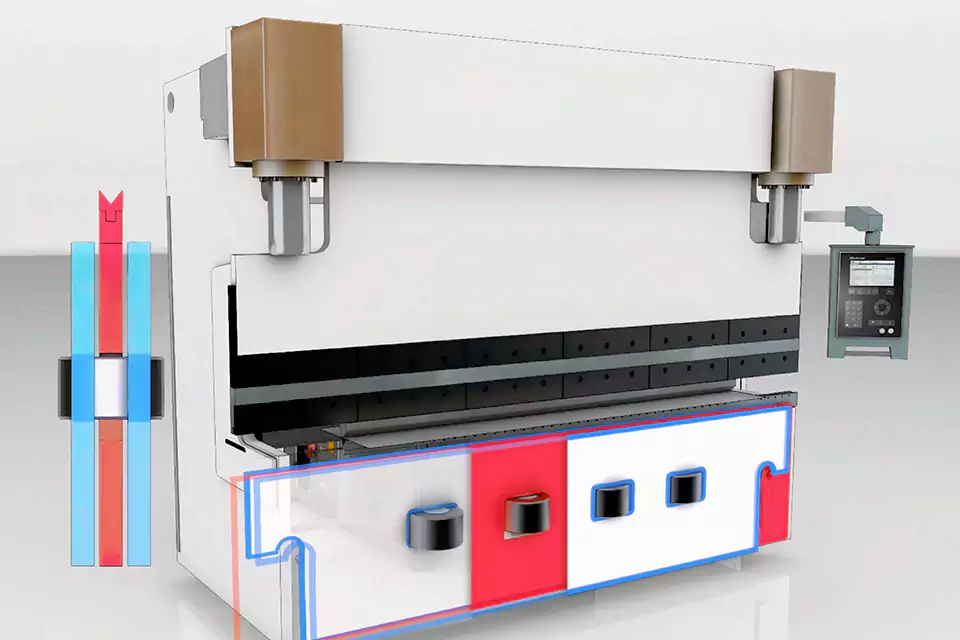

Hydraulic crowning uses several hydraulic cylinders embedded inside the lower beam of the press brake. Controlled automatically by the CNC system, these cylinders adjust pressure in real time based on tonnage and material parameters.

How It Works:

- During bending, hydraulic pressure dynamically changes to ensure perfect straightness.

- Hydraulic pistons apply upward force along the table.

- The CNC calculates deflection in real time and compensates automatically.

Advantages:

- Fully automatic and highly precise.

- Real-time correction maintains perfect angle uniformity.

- Especially ideal for long or high-tonnage press brakes.

- Lower overall machine height compared to mechanical crowning — reducing the total frame size and making export and container transport more convenient.

Limitations:

- Higher cost and more complex system.

- Requires regular hydraulic system inspection and maintenance

📊Comparison Overview

| Feature | Mechanical Crowning | Hydraulic Crowning |

| Control | Manual or motorized | CNC automatic |

| Adjustment | Fixed once set | Real-time dynamic |

| Precision | High | Very high |

| Cost | Lower | Higher |

| Maintenance | Simple | Requires hydraulic maintenance |

| Machine Height | Taller | Shorter (easier for export transport) |

| Special Features | JS RAGOS “Dual Way Compensation” fine-tuning | Automatic deflection control |

| Ideal For | Repetitive, standard bending jobs | Long, complex, high-precision work |

🏭️Why Crowning Matters

Crowning directly impacts bending precision, workpiece consistency, and overall productivity. Without proper crowning, operators must manually correct angles — increasing setup time, material waste, and fatigue.

A well-designed crowning system ensures stable performance and reduces rework, keeping every bend within tight tolerance.