Rexroth Pump-/Valve-Control Drive System or Rexroth DSVP

A pump-controlled drive and a valve-controlled drive system, both optimized for energy-efficient bending, are the two main solutions offered by the Rexroth drive package for press brakes.

Highlights and Advantages:

The pump-controlled variant dramatically lowers energy usage and oil volume by using an axial piston pump and servo motor to provide hydraulic power on demand.

Both versions are appropriate for big tonnage presses (up to 2,500 t and 3,200 t specified) and provide excellent control quality, repeatable processes. Perfect for manufacturers looking for current driving technology, minimal operating costs, and excellent productivity.

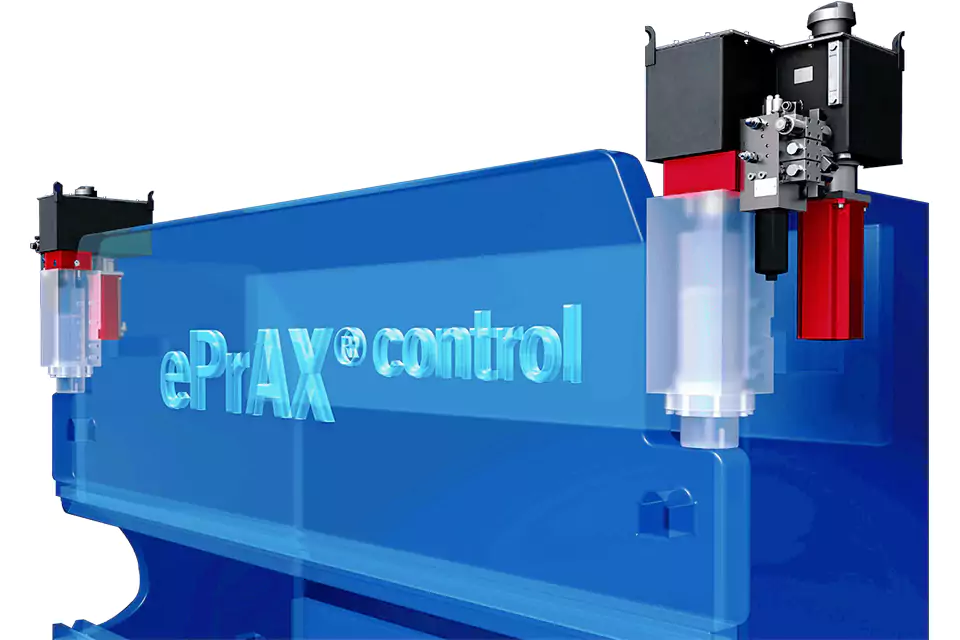

Hawe ePrAX® Hybrid Servo System — Smart, Efficient, and Eco-Friendly

The Hawe ePrAX® Hybrid Servo System combines the potent accuracy of hydraulic control with the high dynamic performance of servo motors to create a new generation of electro-hydraulic drive technology for CNC press brakes.

The ePrAX® system uses a brushless servo motor that is directly coupled to the hydraulic pump to deliver oil flow only when needed. This results in very low energy consumption, extremely silent operation, and excellent positioning precision.

⚙️Principal Attributes & Benefits

- Energy Efficiency up to 65–73 %

Compared with conventional hydraulic systems, ePrAX® dramatically reduces idle energy consumption. - For example, a 130-ton press brake with a 13.5 kW main motor typically consumes around:

- 13.5 kW × 8 h × 300 days = 32,400 kWh per year

- By adopting the ePrAX® hybrid servo system, power savings can reach around 65 %, which equals:

- 32,400 kWh × 65 % ≈ 21,000 kWh saved per year

- Assuming an electricity cost of $0.12 USD per kWh, the annual energy cost reduction is approximately:

- ≈ 2,500 USD per machine per yearThat means the ePrAX® system can pay for itself within 1–2 years through energy savings alone.

✔️Closed-Loop Feedback for Accurate Control

Even in high-speed cycles, precise ram location and consistent bending performance are guaranteed by the closed-loop servo control.

✔️Minimal Noise: Only 50 dB

The production environment is made quieter and more comfortable by the brushless servo motor and on-demand hydraulic actuation.

✔️Eco-Friendly Hydraulic Architecture

The machine is more environmentally friendly because of its small oil tank, lower oil temperature, and less heat generation, all of which prolong the life of hydraulic components.

✔️Elevated Dynamic Reaction

The machine is more environmentally friendly because of its small oil tank, lower oil temperature, and less heat generation, all of which prolong the life of hydraulic components.