Press Brake with Laser Safety Protection | CNC Press Brake

Press Brake Laser Safety Protection: Accurate and Safe Operations

- Precision and safety are the most important in the sheet metal fabrication industry that is as competitive as it is today. Any manufacturer who has to deal with the metal bending of metals of a complex nature needs a machine that offers high accuracy, repeatable performance, and high safety measures. This is where the use of a press brake that has laser safety protection cannot be overlooked.

- JS Ragos is a major manufacturer of press brakes with laser safety that offers more advanced designs, such as a CNC press brake with IRIS safety system, a laser-safe press brake, and an optical-safe press brake. These machines have a combination of laser light curtain protection and automated controls and precision bending systems that allow operators to remain safe and yet record flawless bends each time.

The Need for a Press Brake Laser Safety Protection

Metal forming, particularly when done on a large-scale production, can be hazardous. Conventional press brake operators in pinch areas and unintentional contact, which can have an injurious consequence. A laser safety press brake has removed these dangers with:

- Laser light curtain systems detect any intrusion in the bending zone.

- Automated is used to prevent accidents.

- IRIS optical sensors with high-accuracy positioning and increased security.

CNC press braze with a laser guard not only provides safety, but also enhances productivity by minimizing set-ups and human interventions, making it perfect for the manufacturing processes in industries.

Laser-Protected Press Braise Behind Advanced Technology

The hydraulic press brake has laser protection, and the servo CNC press brake has laser safety, which combines mechanical strength with intelligent automation. Key components include:

Frame and Structure, Heavy Duty

- Long-term rigidity made of welded steel.

- Stress relief heat treatment of stable performance.

- A laser safety system high-speed CNC press brake to operate around the clock.

CNC Controller and Automation

- Complex bending Multi-axis CNC press braze with optical guard.

- An IRIS light curtain on an automatic press brake to make repeatable and accurate bends.

- Offline programming and simulation integrated software.

These characteristics render the machine a high-precision press brake, which is safe and laser-powered to work with delicate sheet metal or under heavy-duty loads.

Characteristics of JS Ragos Laser- Protected Press Brakes

Laser Safety Systems

JS Ragos will use IRIS light curtain technology, which offers:

- Object-detection of objects less than 2 mm.

- Even with custom tooling, it operates safely.

- Status indicators are built in as LEDs.

This guarantees the safety of operation by operators without taking a chance, and at the same time, production efficiency is maintained.

Backgauge and Positioning

The backgauge system ensures that the sheet metal is laid out with a high level of precision, which is within the +-0.03 mm. Features include:

- X, R, and Z axis fast movement.

- Micrometric compensation of accurate bends.

- Multi-axis operation design through modularity.

This automotive fabrication press brake with laser automotive sheet metal bending safety or industrial sheet metal bending provides outstanding outcomes with this type of technology.

Laser-Protected Press Brakes Uses

The CNC press brake with the IRIS safety system of JS Ragos is used by various industries:

- Automobile Fabrication: Bending accuracy of panels and components.

- Construction and HVAC: Bending sheet metal to make roofs, gutters, and ducts.

- Electrical and Electronics: Manufacture of conducting sheets and parts.

- Custom Fabrication: Metal work in art or architecture.

An accurate bending laser-guided press braze produces safe, efficient, and repeatable operations, be it in a CNC sheet metal bending machine with a laser guard or in industrial-scale construction.

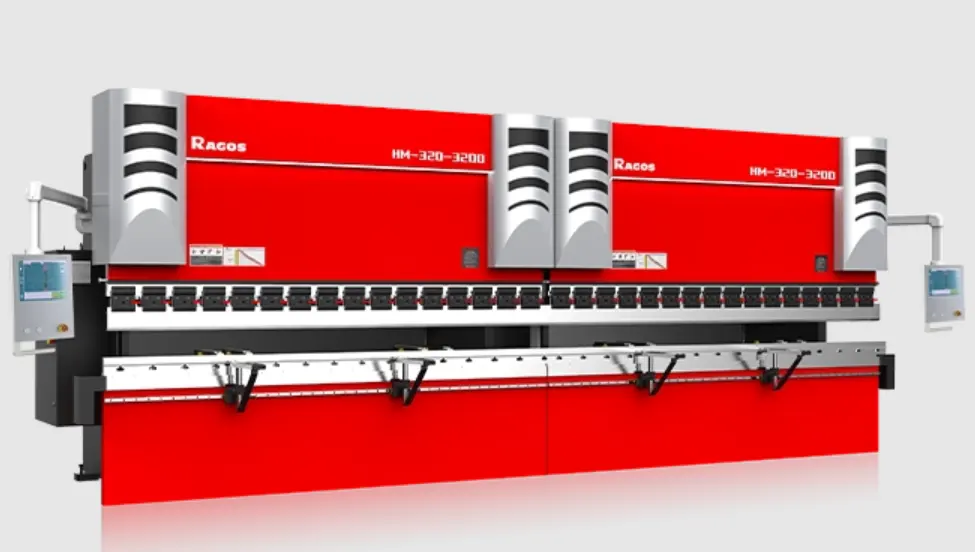

Technical Specifications: Tandem Press Brake

- Pressure: Heavy sheet metal pressure capacity.

- Frame: Welded heavy-duty stress-relieved steel.

- CNC Controller: IRIS light curtain protection, multiple-axis programming.

- Safety: Laser light curtain, optical imaging, and emergency stop.

- Backgauge: High-speed and modular positioning system.

- Tooling: Will work with both standard and custom punches to allow flexible operation.

This laser-guided CNC bending machine is the best option to be chosen because of its high level of performance, high level of productivity, and its non-compromised safety, which any global buyer would choose.

Benefits of Laser Guided Press Brake Investment

- Improved Safety of Operators - IRIS light curtains and optical sensors eliminate accidents.

- Multi-axis Control - +-0.03 mm Precision - Minimal error.

- Automation and Efficiency - Shortens setup time and reduces human errors.

- All-Welded Frame - Welded steel frames and tooling of high quality will guarantee long life.

- Flexibility - Can be utilized across various industries such as the automotive industry, electrical industry, construction industry, and custom fabrication.

A laser safety precision press brake of sheet metal is not merely a machine investment, but an investment in safety at the workplace and production quality.

Press Brake Advantages: Laser Safety Protection

The precision, efficiency, and operator safety combination of a press brake that has safety protection with a laser cannot be equivalent to a traditional press brake. To start with, a laser safety system, which is sometimes combined into an IRIS light curtain or optical guard, is a real-time system that detects any obstruction to avoid any accidents, securing a safe working environment. This minimizes injuries in the workplace and confidence on the operator's part, enabling the team to concentrate on productivity without reducing on the safety.

- Technically, these press brakes provide high-precision bending and multi-axis controls, and CNC program control ensures accurate and repeatable results even on complex sheet metal designs. Such machines as hydraulic or servo CNC press brakes with laser protection make it possible to produce in a shorter time, with fewer setup mistakes, and work with delicate and heavy materials.

- In addition, automation and intelligent software built into these systems can also support the rapid changing of tools, simulation-based planning, and spring-back compensation, which increase speed and consistency. In the automotive sector, the construction sector, and industrial metal fabrication, a laser-secured press brake is a reliable performer; it boasts high-quality bending, and it meets International safety standards.

Conclusion

A laser safety operational press brake is not just any machine, but an investment in work safety and efficiency, and a machine with precision engineering. These press brakes take the safety of the operators into consideration by integrating high-end laser automation, CNC automation, and durable construction for the bending of high-quality sheet metal of high quality. Companies that use such equipment are able to reap more productivity, less risk, and long-term consistency, making it an inevitable tool to use in the contemporary metal fabrication industries. Visit JS Ragos.