Press Brake with Rexroth Hydraulic System | High-Precision Sheet

Excellent, Accurate Sheet Metal Bending Solutions

Accuracy, effectiveness, and consistency are most important in the arena of sheet metal fabrication. The new-day manufacturers require a press brake with a Rexroth hydraulic system, which is characterized by innovative technology, strong construction, and high control systems. You need a Rexroth hydraulic press brake to give you the same high-quality and high-volume door panel components, precision parts, or a high volume of components, and flexibility in your operations.

We are a specialized company that designs and supplies CNC press brakes, which will have Rexroth hydraulic systems to meet various industrial needs at JS RAGOS. To offer excellent performance at a lower cost of operation, our machines have been fitted with high-efficiency hydraulics, intelligent control systems, and ergonomic designs.

What is the Press Brake Rexroth Hydraulic System?

A press braze Rexroth hydraulic system is a high-accuracy hydraulic press braze machine, which employs Bosch Rexroth parts to provide uniform force, precision, and dependability in the bending of sheet metal. Rexroth systems provide, unlike conventional hydraulic press brakes:

- Improved hydraulic circuit efficiency and low-loss hydraulic circuits.

- Accurate regulation of bending angles and tonnage.

- Good service life and durability.

- Obtaining a continuous interface with CNC systems and automation.

These characteristics render Rexroth-controlled press brake machines appropriate for the region of stainless sheet bending to heavy-duty metal processing.

Uses of Rexroth Hydraulic Press Brakes

The hydraulic systems of press brakes with Rexroth are flexible and can be used in various industrial and manufacturing applications:

Sheet Metal Bending: Ideal when working with stainless steel, aluminum, galvanized steel, and thick sheets.

Industrial Sheet Metal Forming: Applicable to large panels, industrial frames, and complicated geometries.

Precision Metal Fabrication: Enforces high-tolerance in high-accuracy bending.

Automated Bending to Mass Production: Saves on labor expenses and enhances the throughput.

Heavy-Duty Metal Bending Solutions: Processes long sheets, thick plates, and high-tonnage.

The machines have an extensive application in hydraulic press brakes of industries and offer impeccable reliability and accuracy.

Technical Models and Specifications

Our Rexroth hydraulic press brakes are available in various models and are used in both ordinary and sophisticated bending.

Advanced Features:

Rexroth Hydraulic Cylinders: Are steady, smooth, and highly repeatable.

Servo-Hydraulic Systems: A composite of the hydraulics with the use of energy-saving servo motors.

Adjustable Bending Angles: Bend freely with accurate control.

Hydraulic Back Gauge Rexroth Control: Precise positioning of the gauge to obtain identical results.

Tonnage Controlled Hydraulic Press: Is the best bending force maintained during operation.

Crowning System: Adjusts to deflection of frames to maintain constant bend angles.

These requirements ensure that our high precision press braze, equipped with Rexroth hydraulic, is applicable in myriads of sheet metal fabrication activities.

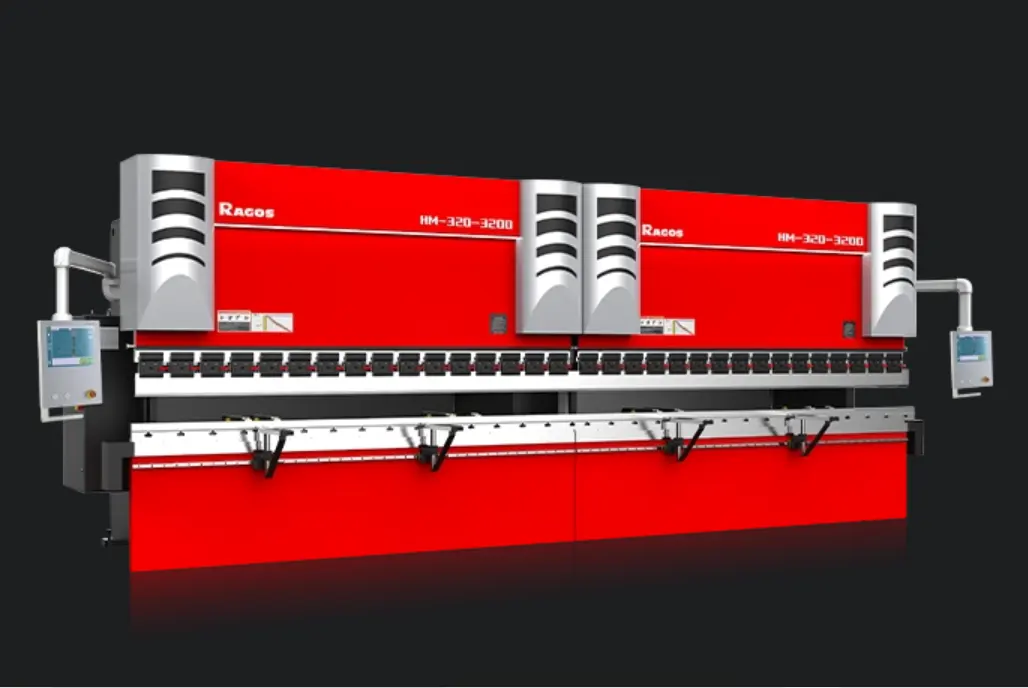

Long Sheet Tandem Press Brake

JS RAGOS Tandem Press Brake: a low-cost tool to bend extra-long sheets. This system can function as:

- Two synchronous long sheet bending machines.

- Independent units of flexible production requirements.

This attribute will guarantee efficiency of operations and easy handling, even among operators who will be new to CNC press brakes.

Maximum Durability Finite Element Analysis (FEA)

Our press brakes involve the use of Finite Element Analysis (FEA) in order to optimize the structural performance. FEA simulates:

- Distribution of stress due to load.

- Machine deformation

- Maximum load capacity

We provide industrial applications with long-term durability and high-bending accuracy, along with the assurance of safe operation due to optimising the frame structure before production.

DA69S CNC System of Improved Control

- The DA69S CNC System provides:

- 24-inch color TFT display that is 24 inches high with high resolution.

- Touch screen functionality is used in industry.

- Interfacing of HDMI and USB to provide an easy connection.

- Proprietary switch to facilitate operation.

The second display solution will improve the convenience of the operator and guarantee the accurate control of the complicated bending operations.

Rexroth Hydraulic System: Availability and Performance

The Rexroth hydraulic system is the heart of our machines, and it ensures:

- High life cycle with the best Rexroth and Hawe parts.

- Good efficiency and performance.

- Modular tank design of oil tanks.

- Anti-corrosion phosphate to prevent corrosion.

- Less sludge growth to ensure the purity of oil.

Together with the strong construction of the machine, these characteristics guarantee reliable operation, minimized downtime, and high bending precision.

Energy Efficiency 200 V JS RAGOS Servo Motors

Our high-efficiency servo motors save 20-30 percent of electricity, unlike traditional motors. Key benefits include:

- Very low noise levels (around 20 dB) of operation.

- Energy-saving performance

- Easy connection with the Rexroth hydraulic systems to achieve maximum bending control.

- Such a combination guarantees high-precision bending of sheet metals and low-operating expenses.

Safety Features: Lazer Safe Iris Light Curtain

Bending operations are very critical of operator safety. Our Lazer Safe Iris Light Curtain offers:

- CLASS 1 block laser protection with optical.

- Precise safety coverage of 2 mm of detection resolution.

- V-tools compatibility as well as non-standard tools.

- Real-time monitoring of state light indicators.

These characteristics reduce the possibility of accidents when using them.

Back Plunge Gauge of Back Positioning

Our hydraulic press brake back gauge system has:

- Linear guide systems and ball screws (TPI, Hiwin).

- Optional Z1-Z2 axes

- Finger adjustment on a micrometric scale.

- Position accuracy: +-0.03 mm

- Z -axis speed: 1000 mm/s; X-axis speed: 400 mm/s.

The back gauge, together with a light curtain to provide some safety, will make sure that every time the bending is done in the same way and in the same place.

Amada Rapid Clamps to Effective Tooling

Our Amada Script type clamps permit:

- Fast installation and unloading of upper press brake punches.

- The change of tools within seconds without tools.

- Constant clamping force to achieve perfect bends.

- Ergonomics to minimize fatigue among the operators.

These clamps enhance production efficiency, particularly when the processes involved are high-volume bending.

Tooling and Bending Follower Systems

Whole Set of Tooling: Machines are delivered at the ready to produce at the moment.

Bending Follower: The large, heavy sheets automatically supported are much safer and more comfortable to the operator.

Automatic Following: Automation lowers labour, sheet stability, and increases consistency in bending.

The systems are used to streamline the sheet metal forming processes in industries and eliminate mistakes in the manufacturing process.

Laser Check Angle Measurement System

Laser Check System guarantees correct bending angles and has a tolerance of greater than +-0.1deg. Features include:

- Completely automatic bend measurement using a laser.

- Springback compensation.

- Value addition on applied bending force.

- Applicable to all types of materials and thicknesses.

The system ensures that it is highly repeatable in bending and gives accurate outcomes in challenging manufacturing situations.

Conclusion

By investing in a press brake with Rexroth hydraulic system of JS RAGOS, it is sure to: Bending of sheet metal of high precision, Servo-hydraulic operation is energy efficient, Protective, comfortable, and user-friendly characteristics. To offer an excellent solution in bending both industrial, commercial, and precision sheet metal, our machines are a product of Bosch Rexroth hydraulic bending technology, servo-motor energy saving, and high-end CNC control systems. A Rexroth hydraulic press brake is reliable, accurate, and efficient, and today, it can be ordered with a quote and put to the test on your sheet metal production.