Press Brake with Servo Motor | CNC Servo Press Brake Solutions

What is a Press Brake with a Servo Motor?

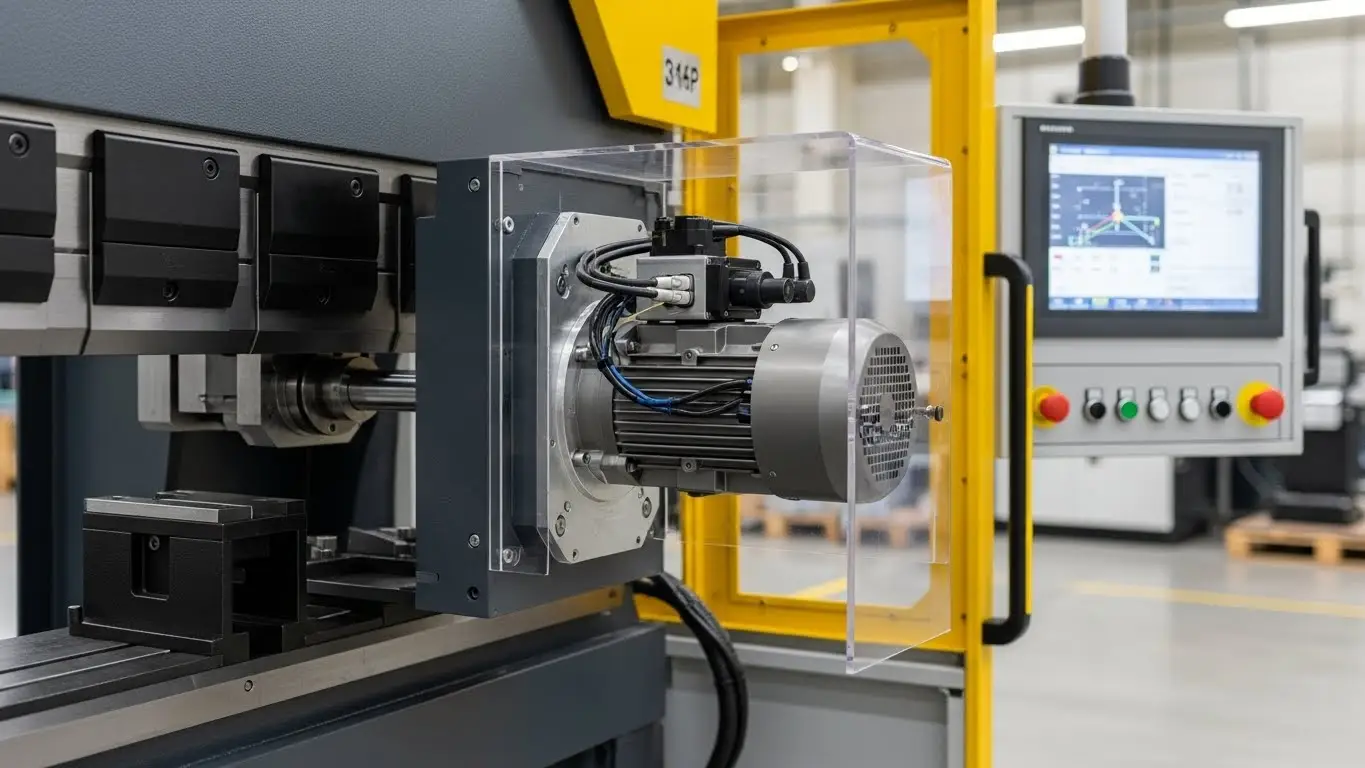

One common form of bending machine is a press brake with a servo motor that uses a servo motor in which the traditional mechanical or purely hydraulic drive has been substituted with a servo-controlled hydraulic drive. The servo motor manages the movement of the ram or bending axis with very high precision, allowing adaptive bending, real-time angle correction, and energy-saving run.

The major features are:

- A high-precision servo press brake control system to achieve high accuracy in bending angles.

- Closed-loop servo motor to have a uniform performance over various tasks.

- Conservation of energy up to 30 percent of electricity usage.

- Synchronization of multi-axis (Y1, Y2, X, R, Z1, Z2) to bend complex sheets.

- Improved safety of operators with built-in light curtains and control systems.

A servo press brake is the best machine with such features to be used in industrial sheet metal fabrication, precision metal forming, and high-tonnage operations.

Press Brae with Servo Motor: CNC Servo Solutions to Sheet Metal Fabrication

- In a rapidly developing industrial sheet metal production industry, accuracy, productivity, and flexibility are no longer a luxury but a necessity. The manufacturers are moving towards the use of press brakes with servo motors as a way of addressing the challenges of complex bending, minimizing the energy expenses, and producing unmatched accuracy. We integrated the latest services and servo technology with the latest hydraulic technology, and CNC controls to offer high-accuracy services, energy-efficient and versatile servo press brakes to all industrial requirements at JS RAGOS.

- No matter what type of operations you are dealing with, stainless steel, aluminum, or mild steel, our machines can provide the specific solution to your problem related to boosting productivity and keeping a high level of quality. We will discuss the world of servo-driven press brakes, their technical benefits, and their use, and the reason why one should go with JS RAGOS as a manufacturer and supplier of servo press brakes.

Technical Characteristics of JS RAGOS Servo Press Brakes

JS RAGOS servo press brakes are a combination of innovative mechanical design, intelligent CNC, and servo control solutions. The technical components and systems that have outstanding features that have been incorporated into our machines are listed below:

Servo Motor and Energy Savings

Our JS RAGOS high-efficiency servo motors run at low noise levels (approximately 20 dB) and save 20-30 per cent of the electricity bill of the traditional Siemens motors. These motors provide:

- Careful, retractable motion on the complicated bending tasks.

- Uninterrupted force usage on varied sheet thicknesses.

- Lower operation cost and high tonnage rates.

Hydraulic System

We use high-quality hydraulic parts from Rexroth and Hawe. Features include:

- Free-standing oil tanks are coated with anti-rust phosphate to be durable.

- Oil purity through the prevention of sludge.

- Extended operation and stable operation, reducing downtimes.

CNC & Control Systems

Our press brakes can be combined with Delem, ESA, and Cybelec, and high-end equipment, such as DA69S CNC systems:

- 24" high-resolution color TFT having industrial grade touchscreen.

- HDMI and USB connecting to offline programming.

- Proprietary switches and automatic connection with 3D bending simulation software.

- Adaptive bending precision with real-time angle correction.

Tandem Press Braze Capability

The JS RAGOS Tandem Press Brake is an intelligent device in case of long sheets:

- They are used as two synchronized machines on long parts.

- Flexible production possible by operating independently.

- Easy and user-friendly to the novice, and with industrial-grade accuracy.

Finite Element Analysis (FEA)

FEA analysis is performed on all JS RAGOS press brake frame simulating stress, deformation, and load distribution:

- Maximum frame strength ensured.

- Ensures extreme accuracy and survival in the actual working conditions.

- Saves on maintenance expenses and increases its life.

Tooling & Amada Quick Clamps

- The position of upper press brake punches can be tool-free changed and set up in less time.

- It is designed with a high level of accuracy in bending due to ergonomic design and alloy steel of high strength.

- Ready tooling packages were on hand to start production.

Bending Follower System

- Automatic sheet support for bending.

- Holds the weight of large, heavy, and long sheets up to 250 kg per arm.

- Lessens operator stress as well as improves safety in the workplace.

Safety Features

- Lazer Safe Iris Light Curtain for optical protection.

- The image is provided using a camera with a detection resolution of 2 mm.

- Safety of the operator without loss of productivity.

Uses of Servo Press Brakes

Press brakes with a servo motor are extensively employed in factories that need precision metal forming:

- Sheet Metal Fabrication: This is ideal for bending thin or thick sheet metal with precise angles.

- Automobile Industry: Manufactures accurate automobile components of standard quality.

- Aerospace Components: Specialty bending of aerospace alloys.

- Construction & Architecture: Stainless steel and aluminum bending of the panels, doors, and structural elements.

- Heavy-Duty Industrial Parts: The Servo press brakes are used in long, heavy sheets, which have high tonnage capacity.

Why JS RAGOS Servo Press Brakes?

We innovate, are reliable, and easy to use at JS RAGOS:

- Custom Configurations: Developed servo press brakes to your production requirements.

- Global Export Solutions: Export-level machines.

- After Sales: Complete maintenance and service.

- Smart CNC: 3D bending, measuring angles, and offline programming in the current production plants.

Our products are fully servo press brakes, including:

- Hydraulic press brakes, which are servo-controlled.

- Servo-driven CNC press brakes.

- Servo press brakes of high precision.

- Precision servo press brake machines.

- Servo press brake tools in industries.

Purchase and Invest in a Servo Press Brake

- Be it a purchase of a servo press brake machine, investment in an energy-saving servo hydraulic solution, or an upgrade to a smart CNC servo press brake system, JS RAGOS is your reliable business partner. Check out our Tandem Press Brake HG/HM models, which can run between 40T and 600 T, and controllers of Delem, ESA, Cybelec, and Step.

- Ask us for a quote now using our site: JS RAGOS Servo Press Brake. Our specialists will assist you in deciding on a machine that will best fit your industrial practice.

Conclusion:

One thing is that in the modern competitive manufacturing industry, a press brake with servo motor is not only a technological improvement but a strategic step. JS RAGOS servo press brakes offer the capability of managing complex and heavy-duty multi-axis synchronized bending processes using high precision, energy efficiency, smart CNC control, and ease. Our servo-controlled sheet metal bending machines are used in industrial fabrication for automotive and aerospace products, providing them with high productivity, low operation cost, and quality products.