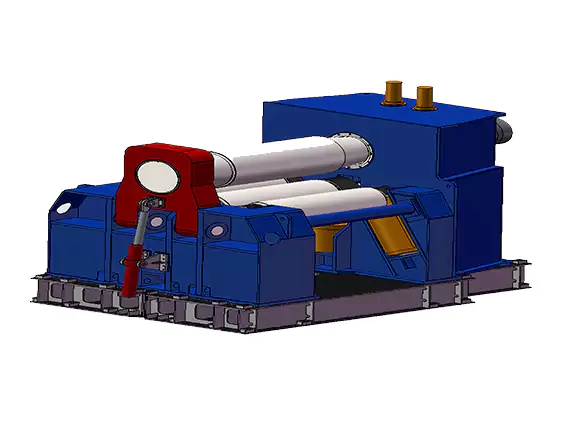

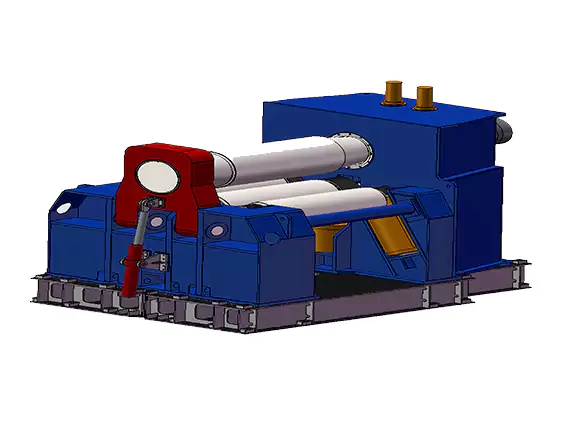

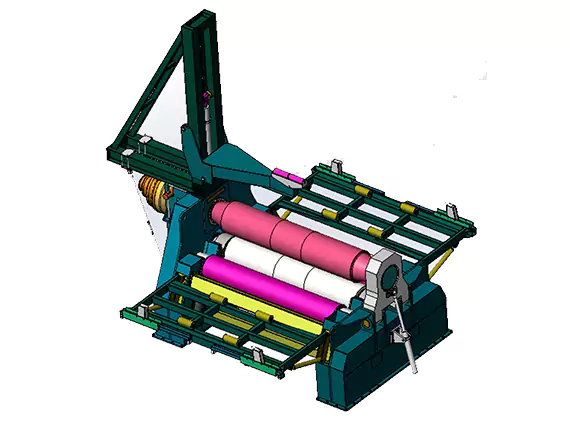

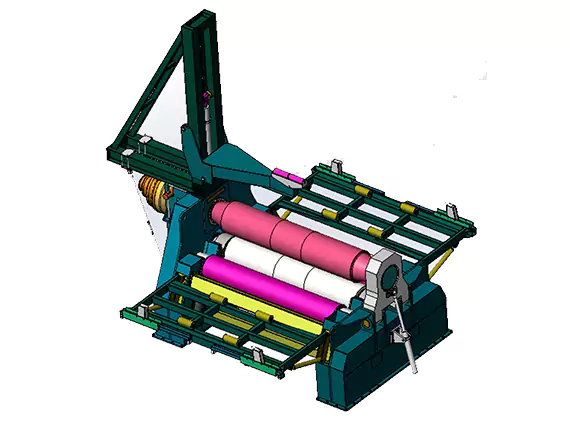

4 Rolls Machine

Our 4-roll plate rolling machine is available in linear or arc type, providing flexibility to meet different production needs. It is customizable and widely used in industries such as shipbuilding, pressure vessels, tanks, and other heavy plate applications, offering reliable performance for both straight and curved plate forming.

-

High Precision CNC-controlled rolls ensure accurate, consistent forming.

-

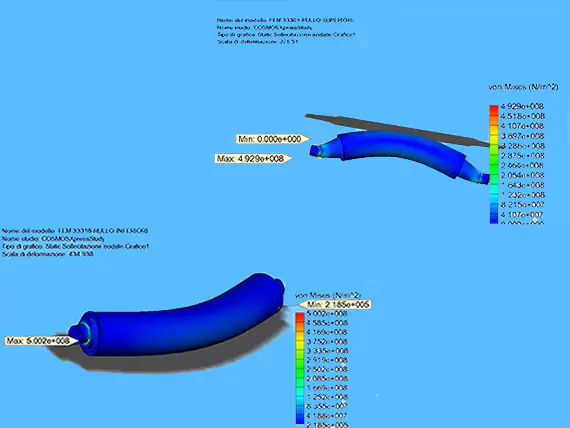

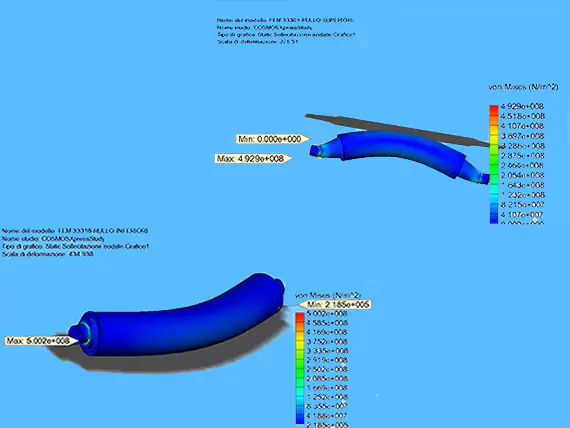

Strong & Durable FEA-designed frame and hardened rolls ensure long life.

-

Efficient Operation Planetary drive and hydraulic systems boost productivity.

Reliable Structure

Our machines are built with a high-strength frame designed through Finite Element Analysis (FEA) to ensure maximum rigidity and precision. All main components undergo heat treatment to enhance durability and long-term stability.

Request A Quote

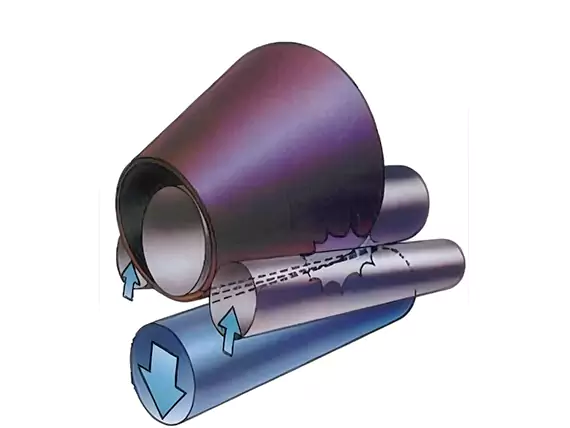

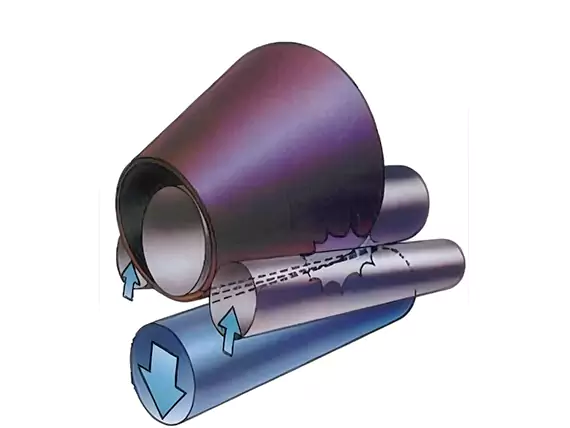

Cone Rolling Device

Equipped with a dedicated cone rolling system, allowing the machine to easily form conical shapes with high accuracy and efficiency.

Request A Quote

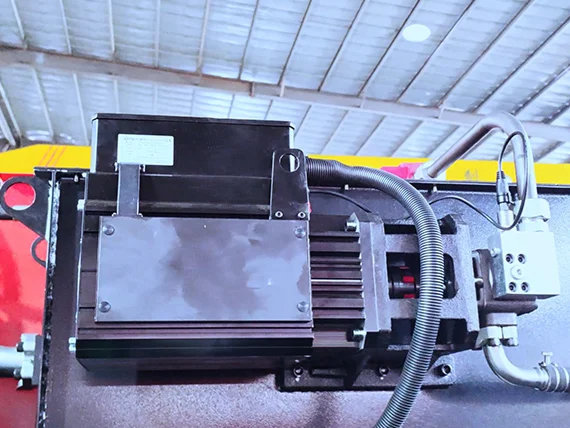

Planetary Gear Driving System

By distributing the load uniformly across several gears, the planetary arrangement provides strong and steady torque to the rollers with little energy loss, in contrast to traditional heavy transmission systems that waste energy through multi-stage mechanical losses.

A separate hydraulic motor and planetary gearbox that are directly connected on the same axis power each roll. Longer mechanical life, improved bending precision, and smoother operation are made possible by this design, which removes torque loss during transmission.

Request A Quote

Top & Side Support

For large-diameter cylinders, an upper and lower supporting device is provided to prevent material collapse and ensure roundness during the rolling process.

Request A Quote

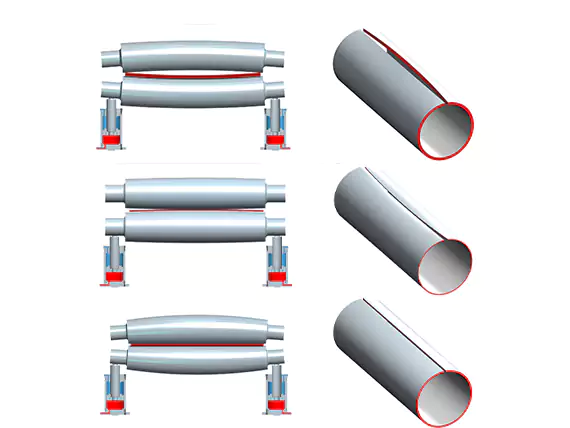

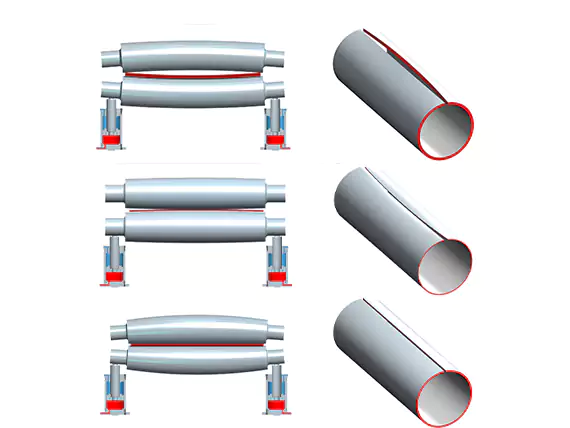

Crowning System

During the bending process, the pressure applied to the rolls can cause slight deflection in the center, leading to uneven curvature or flat zones along the plate. To eliminate this, our machines are equipped with a precision-engineered crowning compensation system.

Each roll is CNC-machined with a calculated crown profile that offsets deflection under load. When bending thick or wide plates, the crown ensures that pressure is evenly distributed across the entire plate width, maintaining a perfect cylindrical shape.

Request A Quote

Roller

All rolls are forged solid and undergo induction hardening to achieve a surface hardness of 42–55 HRC, significantly improving wear resistance and extending service life. In addition, rolls receive a special surface treatment for superior hardness and smooth rolling performance, CNC machined with an optimized crown, and induction hardened up to 54 HRC for superior strength and surface durability. Optional polished rolls are available for high-finish requirements.

Request A Quote

Main Features

-

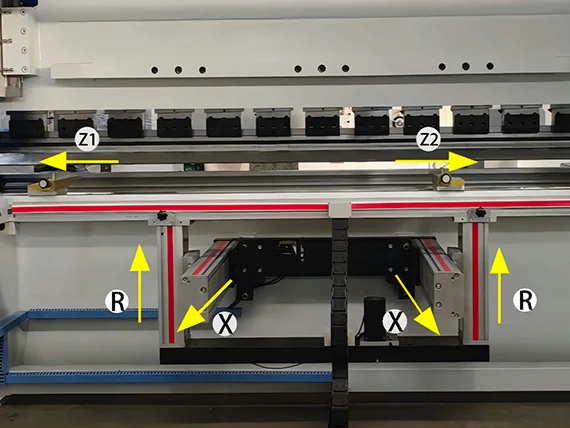

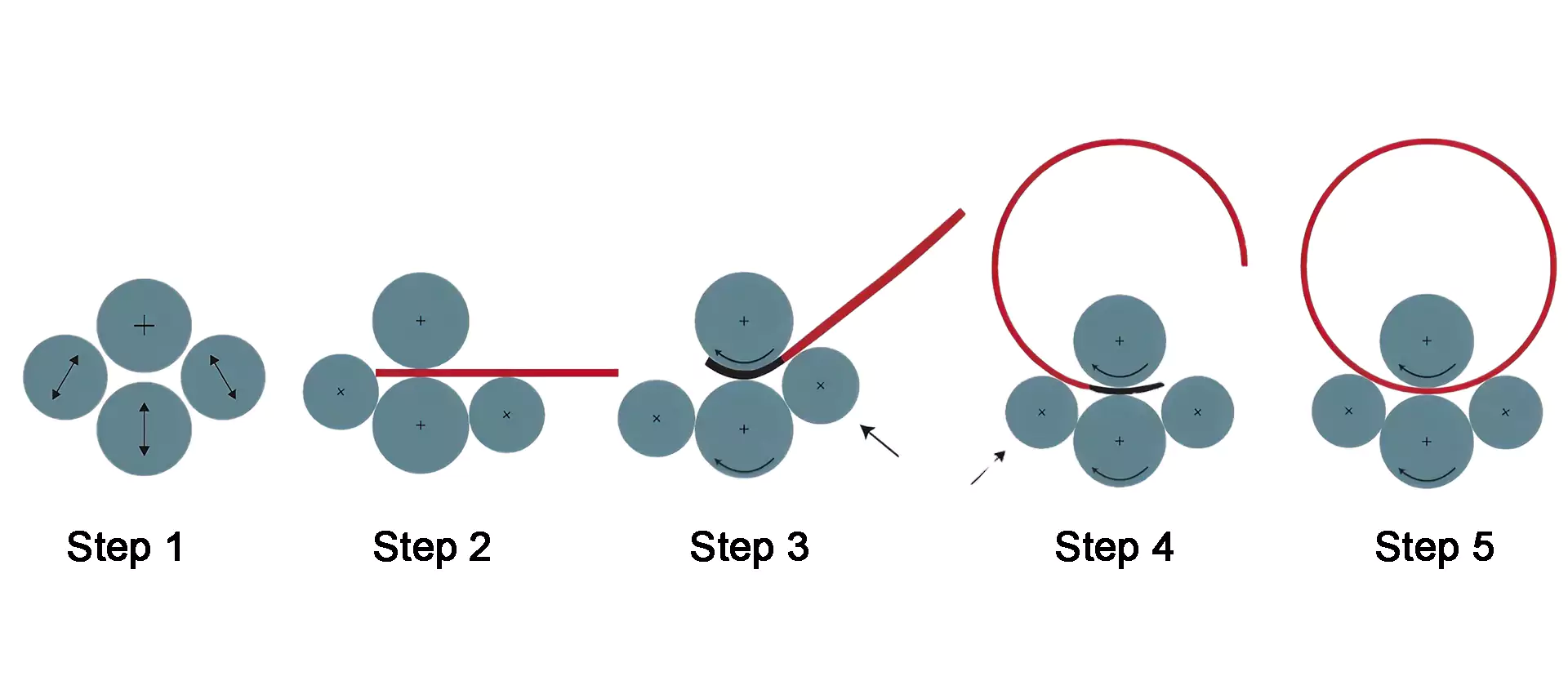

- Planetary Side Roll Movement

The side rolls adopt a planetary movement structure, ensuring smooth and precise positioning with enhanced forming accuracy.

- Planetary Side Roll Movement

-

- Digital Roll Positioning

The machine is equipped with three independent digital readouts, allowing operators to easily monitor and control roll positions during operation.

- Digital Roll Positioning

-

- Dual Working Speed

Two selectable speed modes support both precision forming and high-speed rolling for improved production flexibility.

- Dual Working Speed

-

- Cone Rolling Capability

Designed with a dedicated cone bending system, ideal for producing conical shapes with consistent geometry.

- Cone Rolling Capability

-

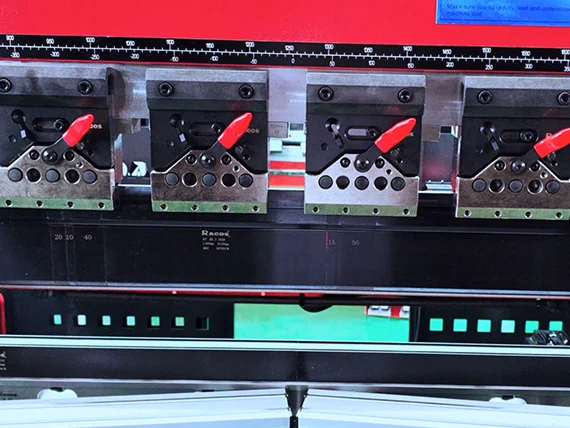

- Hardened and Machined Rolls

All rolls are made of 1050 carbon steel, CNC machined with an optimized crown, and induction hardened up to 54 HRC for superior strength and surface durability. Optional polished rolls are available for high-finish requirements.

- Hardened and Machined Rolls

Hydraulic Systems and Support

Includes a hydraulic balancing system for the side rolls and a wedge-bar clamping system on the bottom roll, ensuring stable operation under load.

Upgrade Solutions

If you need to purchase separate accessories or services to renovate the machine, you can learn more through the link below.

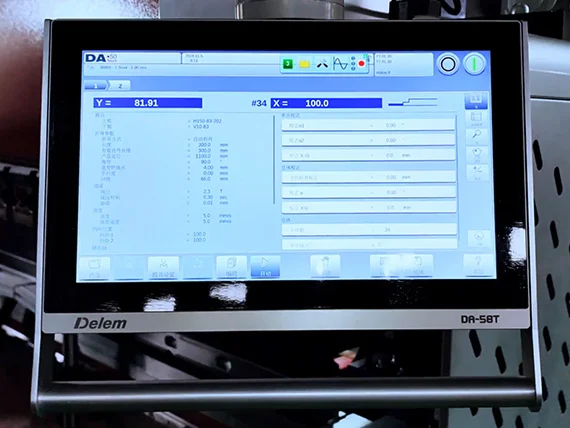

CNC Control System

Back Gauge Modifcation

Safety Arrangements

Crowning System

Tooling Clamping System

Hybrid Servo ECO Function

Hybrid DSVP System

Bending Off-line Software

Angle Measurement Device

Frequently Asked Questions

-

What is a plate rolling machine and how does it work?

-

What are the main types of plate rolling machines?

-

What is the difference between a 3-roll and 4-roll machine?

-

What is a straight edge (flat-end) in plate rolling?

-

How is roll deflection compensated during pre-bending and rolling?