Bending Cell

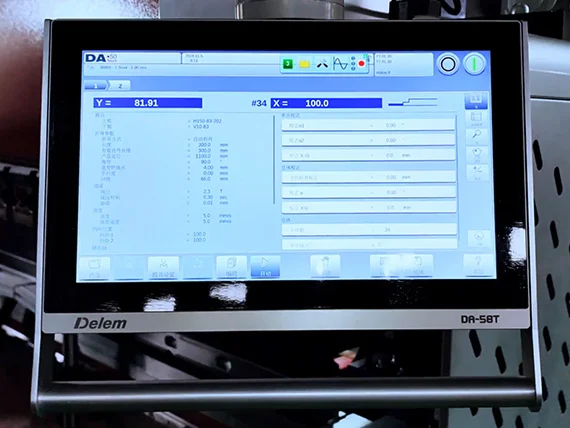

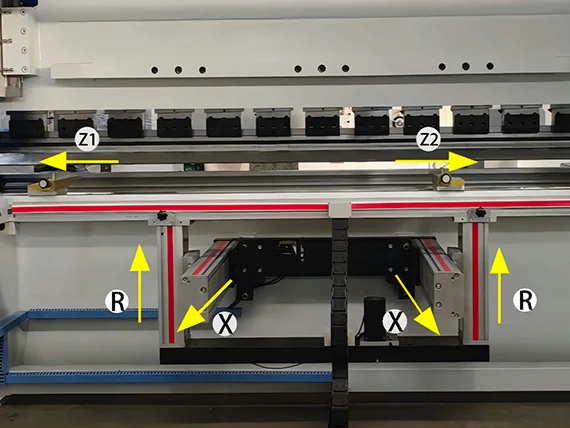

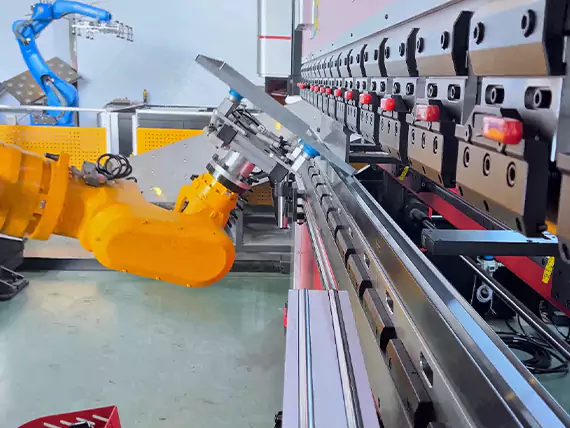

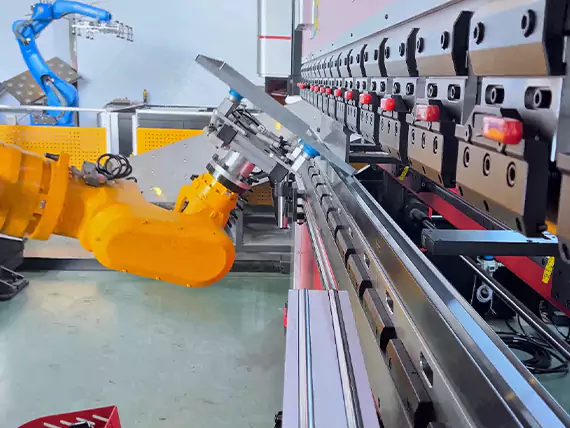

The Press Brake Bending Cell integrates robotic automation with advanced CNC press brakes for high-efficiency, flexible sheet metal bending. It supports multi-brand robots (FANUC, KUKA, ABB, Yaskawa) and intelligent control systems (DELEM, ESA, Cybelec) to ensure precision, speed, and safety. Ideal for smart factories seeking consistent quality and reduced labor.

-

Model HG/HM

-

Capabilities 40T - 600T

-

Controller Brand Delem/ESA/Cybelec/Step

Flexible Bending Solution

By integrating optional bending robots from FANUC, KUKA, ABB, and Yaskawa, we provide customized automation solutions designed directly from customer drawings. Our systems can be configured with high-quality tooling and clamping systems such as Wila, Amada, and Rolleri, as well as specialized fixtures, to achieve maximum flexibility and precision.

This tailored approach allows for significantly higher production efficiency, reduced labor intensity, and improved consistency in bending quality. Combined with intelligent automation, our solutions ensure reliable, high-speed processing that seamlessly adapts to the needs of modern smart factories.

Request A Quote

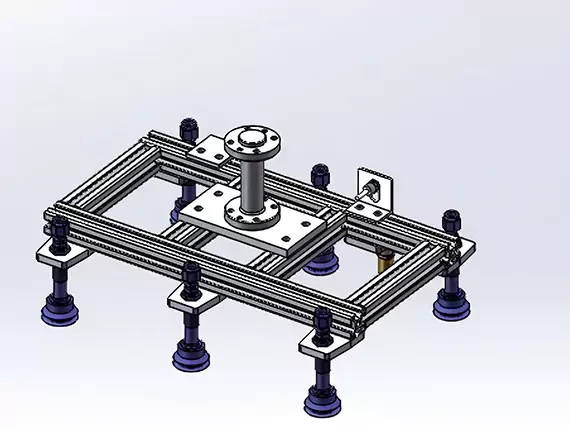

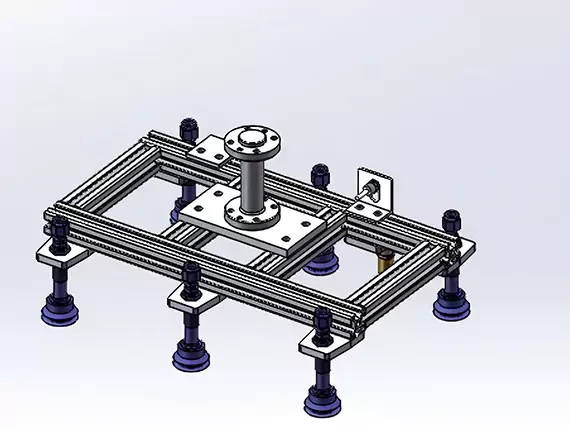

Custom Gripper by JS RAGOS

We design and build custom end-of-arm grippers tailored to your parts, processes, and robots. From thin sheet handling to heavy plate, tube, and enclosure assemblies, our grippers are engineered for high stability, fast cycles, and scratch-free handling—perfect for bending cells, welding lines, and automated press brake loading/unloading.

Request A Quote

Bending Cell Layout Overview

A modern Bending Cell is designed for efficient, automated sheet metal bending operations. Its layout is optimized to ensure smooth material flow, precision, and operator safety. The main components typically include:

- Loading Plate– Where raw sheets are placed, ready for bending.

- Alignment Table– Ensures sheets are correctly positioned for accurate bends.

- Bending Area– The main press brake or bending machine.

- Flipping/Rotating Table– For parts that need multiple bends on different sides.

- Unloading Plate– Where finished parts are collected.

- Floor Cabinets– Storage for tools and accessories, keeping the workspace organized.

The 7-axis Bending Robot

7-Axis Bending Robot

Our 7-axis bending robot is designed for maximum flexibility and efficiency in sheet metal bending.

- Long Workpiece Handling– Easily bends longer parts with high precision.

- Future Scalability– Ready to handle more parts as production demands increase.

- Flexible Positioning– The robot can be moved aside, allowing operators to manually bend additional parts when needed.

- High Efficiency– Works seamlessly with press brakes and automated lines to boost productivity.

Request A Quote

Regrip station/Repositioning station

A flipping table is used in bending operations to turn or rotate workpieces, allowing multiple bends on different sides. It improves workflow efficiency, reduces manual handling, and ensures precise positioning for complex parts.

Request A Quote

Light Curtain

DSP LASER protects the pressbrake operator from the danger of crushing that can take place accidentally between the moving part of the machine and the fixed one.The project idea used for this device is the one to fit out the moving pert of the pressbrake with a protection zone.

This is a volume of suitable and special dimensions generated by DSP LASER and placed under the upper tool vertex at a higher distance than that the machine requires to stop.So the protection zone, that moves together with the mobile part because integral with it, advances the race of this one towards the fixed pert. An obstacle (for example the Operator fingers) when entering the protection zone. Is detected immediately causing consequently the interruption of the mobile part motion.

Request A Quote

Laser Check Angle Measurement System

The Laser check system, developed with Data-M & Vision Components, ensures highly accurate bend angles after just a single bending operation.

As a fully automatic, laser-assisted bend angle measurement solution for CNC press brakes, iMeasure delivers precise angle detection regardless of material type or thickness. With an accuracy exceeding ±0.1°, it achieves a level of precision previously unattainable.

The system automatically corrects bending angles by projecting a laser beam onto the sheet surface, which is then detected by a camera. By calculating the angle between the laser beam and the camera axis, the system determines the actual bend angle, compensates for springback, and optimizes the applied force for perfect results.

Request A Quote

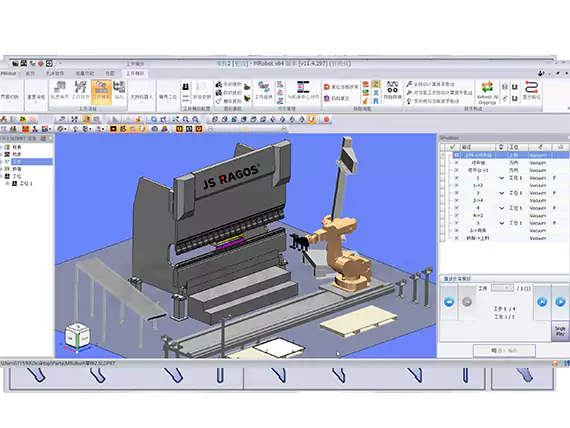

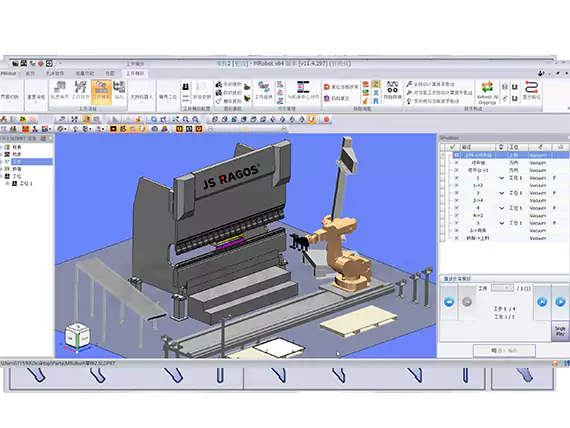

3D Offline Software

Currently compatible with Kuka, Yaskawa, ABB, Fanuc, and Mitsubishi robots — more brands coming soon.

✨ Main Features of Our 3D Software

- Automatic gripping & path calculation→ Fast and accurate setup.

- Visual interactive gripping→ Easy real-time adjustment.

- Manual fine-tuning→ Adjust robot paths with simple control points.

- Supports vacuum & clamp grippers→ Flexible for complex tooling.

- Supports rail systems→ Ideal for large bending cells.

- Easy stacking setup→ Faster, cleaner production flow.

- CNC code for both machine & robot→ Smooth communication.

- Synchronized operation→ Stable and efficient bending.

Request A Quote

Upgrade Solutions

If You Need To Purchase Separate Accessories Or Services To Renovate The Machine, You Can Learn More Through The Link Below.

CNC Control System

Back Gauge Modifcation

Safety Options(NR 12)

Crowning System

Tooling Clamping System

Bending Follower

Hybrid DSVP System

Bending Off-line Software

Angle Measurement Device

Frequently Asked Questions

-

What Robot Brands Can Be Integrated?

-

Can The System Be Customized For Different Parts?

-

How Accurate Is The Bending Process?

-

Is Manual Operation Still Possible?

-

What Safety Systems Are Included?