CNC V-Grooving Machine

The NCVM-3200 V-Grooving Machine is a high-end CNC metal planing solution designed for precision sheet metal bending. Built with a full steel welded body and tempered to minimize deformation, the NCVM-3200 delivers exceptional accuracy, stability, and durability. Its advanced CNC system enables fully automatic processing, while a precise electro-pneumatic control design ensures flexible operation, high efficiency, and low noise — all with zero environmental pollution.

-

Model NCVM-3200

-

Power Supply 380V, 50Hz (±10%)

-

Relative Humidity 20–80% (non-condensing)

Double-headed eight knives (Planing Easier)

Korean KORlOY high quality steel processed by quenching process to improve the overall knife body strength andsurface quality, high temperature resistance, improve the life of the knife body and anti-vibration, high hardness, highsharpness, sturdy and durable, planing more easily.

Request A Quote

Double-headed eight knives (Planing Easier)

Precise positioning to ensure that the metal plate for V-shaped slotting does not run, so that the workpiece bending afterthe radius of the prismatic arc significantly reduce the remaining plate thickness at the bending after the creation of theslot, the deformation force during bending will also be reduced accordingly, so the surfiace ofthe workpiece after bendingdoes not exist creases.

Request A Quote

Technical Specifications

For more detailed specifications, please don’t hesitate to contact us!

| Model | NCVM-3200 |

| Processing Length | 3200 mm |

| Processing Width | 1250 mm |

| Thickness Range | 0.5 – 6 mm |

| Processing Speed | 0–120 m/min |

| Feeding Speed (Y-axis) | 0–20 m/min |

| Tool Holder Travel (Z-axis) | 0–20 m/min |

| Precision | ±0.01 mm |

| Weight | 11,200 kg |

| Power System | 1.5 kW / 8L / 10Mpa |

| Minimum Margin | 8 mm |

| Maximum Feeding Distance (Y-axis) | 1600 mm |

Upgrade Solutions

If you need to purchase separate accessories or services to renovate the machine, you can learn more through the link below.

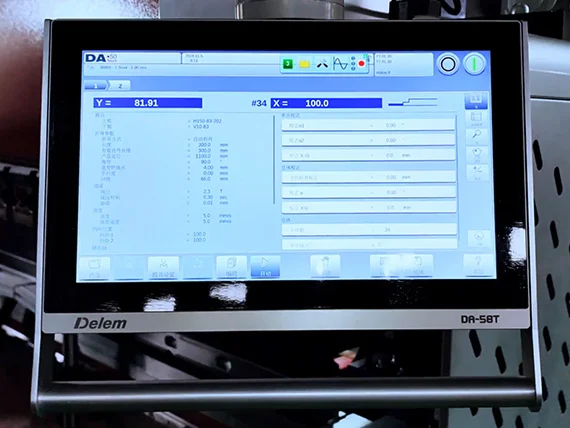

CNC Control System

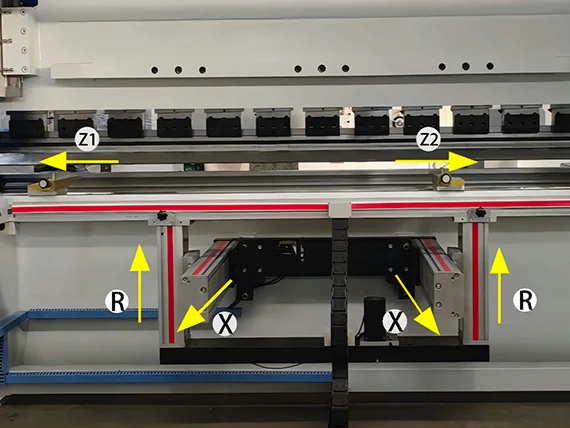

Back Gauge Modifcation

Safety Options(NR 12)

Crowning System

Tooling Clamping System

Bending Follower

Hybrid DSVP System

Bending off-line software

Angle Measurement Device

Frequently Asked Questions

-

1. How does a CNC V grooving machine improve bending accuracy in sheet metal processing?

-

2. What materials and thickness ranges are suitable for CNC V grooving?

-

3. How is groove depth controlled during operation?

-

4. Does the machine support automatic tool compensation and wear detection?

-

5. Can a CNC V grooving machine be linked with bending lines or MES systems?