Electric Press Brake

The Press Brake Features A High-Strength Welded Frame, Delem Da66s Cnc Control, And Lazer Safe Iris Protection. Dual Grating Rulers Ensure ±0.03 Mm Accuracy, While Amada Quick Clamps And 42crmo Tooling Offer Fast Setup And Long Durability.

-

Model NG-4015

-

Pressure 40ton

-

Power 8.6*2Kw

High Strength Frame

🔹 Frame Construction

The machine adopts a heavy-duty welded steel frame, providing excellent rigidity, strength, and durability for long-term stable performance.

🔹 Heat Treatment & Shot Blasting

After welding, the entire frame undergoes stress-relief heat treatment and shot blasting, which effectively removes internal stress, minimizes deformation, and enhances structural stability.

🔹 CNC Precision Machining

All critical mounting surfaces are machined in a single clamping operation on a CNC vertical machining center. This ensures outstanding parallelism and perpendicularity, delivering superior accuracy and consistent bending quality.

Request A Quote

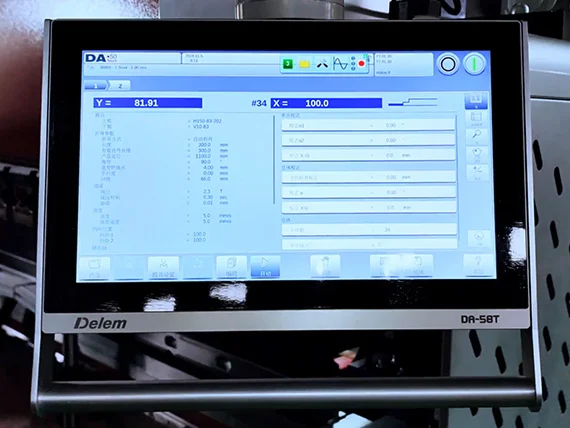

CNC Controller(DA66S)

- 2D graphical touch screen programming mode

- 3D machine representation, in simulation and production

- 24" high resolution color TFT

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-S2D offline software

Request A Quote

Lazer Safe Iris Light Curtain

- Optical protection functions:support

- Optical imaging functions:support

- Laser transmitter: CLASS 1 Block laser

- Receiver: Camera receiver with integrated image processor

- Maximum recommended optical range: 8 meters

- Sensing area: 30mm(H)x30mm(W)

- Minimum object detection resolution: 2mm

- Connector type: M12 12pin

- Tool compatibility: V tools and non-standard tools

- Integrated status LEDs: support

Request A Quote

Synchronous Control

On JS Ragos machine, two grating rulers eliminate accuracy variations brought on by guide rail wear, achieving accurate synchronization and improved structural stability.

Smooth movement and dependable synchronization are guaranteed by a pair of high-precision ball screw drives, and damage from eccentric loads is avoided by the carefully made hinge construction.

Superior bending accuracy and long-term operational reliability are guaranteed by the system's highly accurate placement, which is achieved using real-time grating ruler feedback management.

Request A Quote

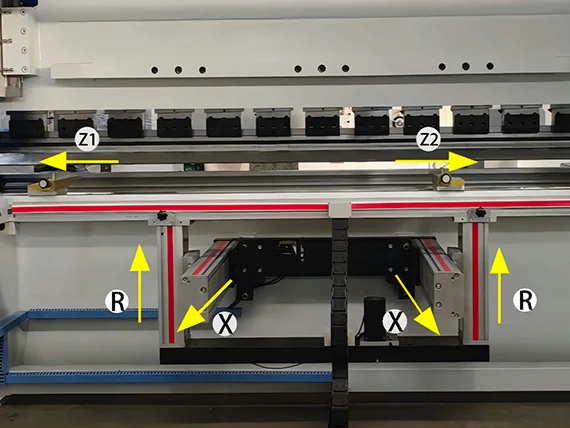

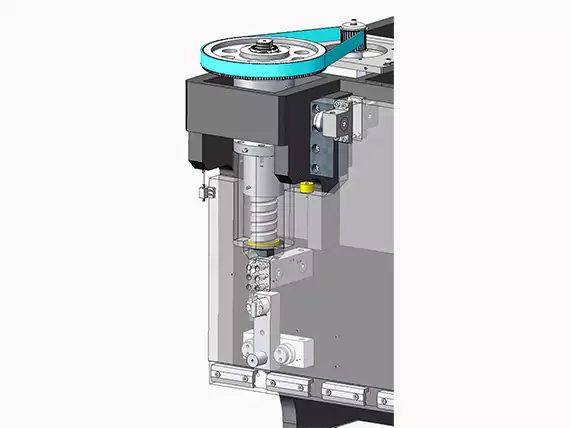

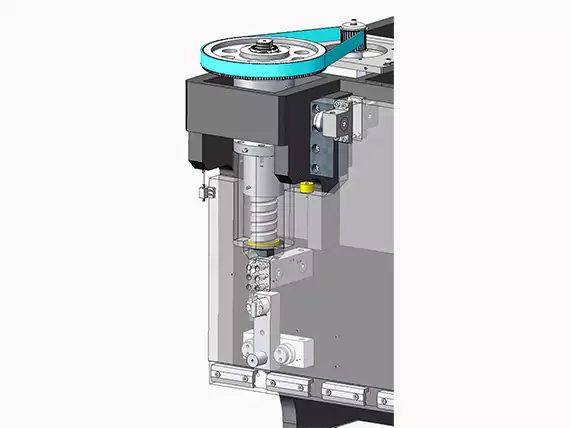

Backgauge

High-Precision Backgauge System

Our press brakes are equipped with a high-precision backgauge system, designed to ensure fast, accurate, and repeatable positioning of sheet metal. Using ball screws, linear guides, and precision belts, the system guarantees smooth movement and long-term reliability.

Key Features:

- ±0.03 mm positioning accuracy

- High-speed movement on X, R, and Z axes

- Micrometric adjustment with double-stop fingers

- Thin sheet support system (SPA) with 30 kg load capacity per support

- Modular design, flexible for 4, 6, or multi-axis configurations

Request A Quote

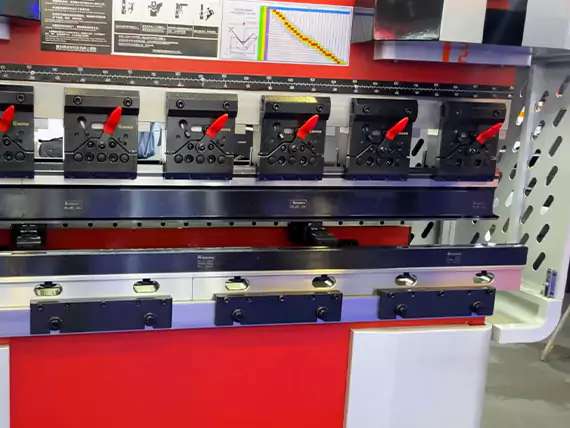

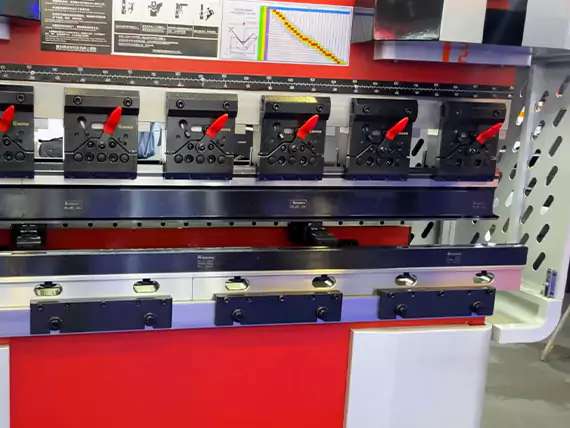

Amada Style European One Touch Press Brake Punch Holder

Fast Loading

Smaller sectionalized punch can be snapped in and out from the front of holder.

Safety Groove

A special camp plate is available which mounts the punch to the machine utillzing the safety groove on the top potion of the punch holder. This special clamp plate prevents punch from dropping when horizontal movement of clamp is required.

Operator Safety

Drop prevention bar prevents punches from falling out of the punch holder during setup increasing operator safety. Once the punch is inserted into the clamp, the punch can be moved to any location along the brake bed eliminating the possibility of it falling out of the clamp.

Request A Quote

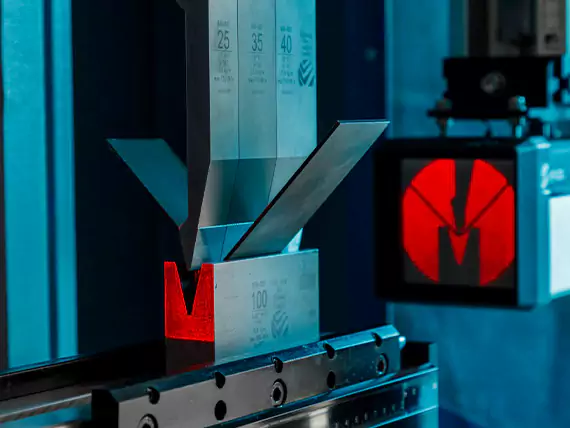

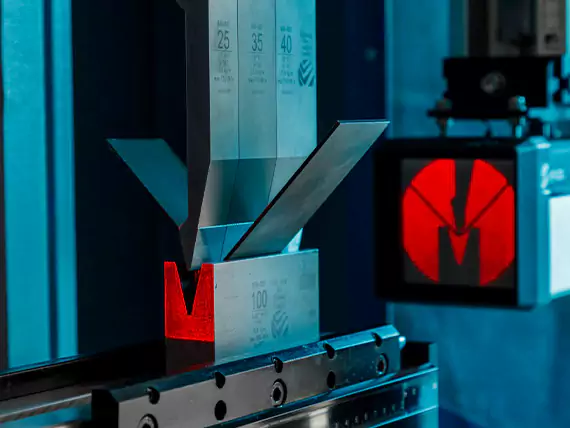

Punch & Die

We provide customized press brake tooling to meet different bending applications. All our tools are made from 42CrMo high-strength steel, with heat treatment to ensure excellent hardness, durability, and long service life.

We also offer segmented tooling services, allowing flexible setups for different bending lengths and shapes. Our tooling can be customized to fit Wila, Amada, and other standard tool systems, ensuring compatibility and easy installation.

Request A Quote

Technical Specifications

For more detailed specifications, please don’t hesitate to contact us!

| Model | NG-4015 | NG-3512 | NG-2508 | NG-6020 | NG-8025 | NG-1003 |

| Pressure | 40ton | 35ton | 25ton | 60ton | 80ton | 100ton |

| Length(mm) | 1500 | 1200 | 800 | 2000 | 2500 | 3200 |

| Working table height(mm) | 855 | 810 | 805 | 855 | 830 | 855 |

| Daylight(mm) | 420 | 420 | 420 | 420 | 420 | 500 |

| Throat(mm) | 400 | 400 | 300 | 400 | 400 | 400 |

| Stroke(mm) | 150 | 150 | 150 | 150 | 150 | 200 |

| Empty loading speed | 200mm/S | 200mm/S | 170mm/S | 150mm/S | 180mm/S | 180mm/S |

| Working speed | 10-30mm/S | 10-30mm/S | 10-30mm/S | 10-30mm/S | 10-30mm/S | 10-30mm/S |

| Backgauge stroke(mm) | 500 | 500 | 500 | 500 | 600 | 600 |

| Backgaue speed(mm/s) | 250mm/S | 250mm/S | 250mm/S | 250mm/S | 250mm/S | 250mm/S |

| R axis stroke(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| R axis speed | 130mm/S | 130mm/S | 130mm/S | 130mm/S | 130mm/S | 130mm/S |

| Distance between frame | 1430mm | 1130mm | 635mm | 1930mm | 2190mm | 2870mm |

| Axis | 6axis | 4axis | 3axis | 6axis | 6+1axis | 6+1axis |

| Power | 8.6*2Kw | 5.5*2Kw | 8.6Kw | 8.6*2Kw | 20*2Kw | 22*2Kw |

| Weight | 3900Kg | 2900Kg | 1900Kg | 4500Kg | 6800Kg | 8200Kg |

| Dimension(LxWxHmm) | 2050X1800X2270 | 1740X1800X2200 | 1250X1600X2130 | 2560X1810X2440 | 3060X1850X2600 | 3760X1950X2700 |

| Total power | 18.8Kw | 11.8Kw | 9.4Kw | 19.5Kw | 42.3Kw | 46.3Kw |

| Voltage | 380V | 380V | 380V | 380V | 380V | 380V |

Upgrade Solutions

If you need to purchase separate accessories or services to renovate the machine, you can learn more through the link below.

CNC Control System

Back Gauge Modifcation

Safety Options(NR 12)

Crowning System

Tooling Clamping System

Bending Follower

Hybrid DSVP System

Bending Off-line Software

Angle Measurement Device

Frequently Asked Questions

-

How does an electric press brake differ from hydraulic models in motion control?

-

What are the energy efficiency benefits of using an electric press brake?

-

Is bending force consistent across the stroke in electric press brakes?

-

Can electric press brakes be used for high-mix, low-volume production?

-

Do electric models require less maintenance than hydraulic presses?