Hybrid CNC Press Brake

Compared with traditional press brakes, CNC press brakes deliver higher accuracy and efficiency, increasing productivity by up to 30% while reducing electric bills by 20–30%.

-

Model HG/HM

-

Capabilities 40T - 600T

-

Controller Brand Delem/ESA/Cybelec/Step

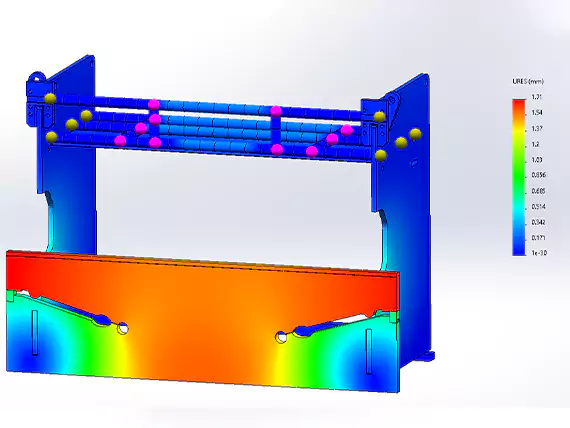

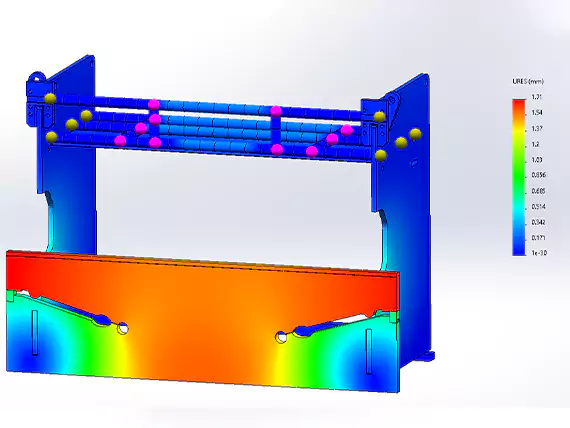

FEA Analysis

Finite Element Analysis (FEA) is applied in our press brake design to simulate and optimize structural performance under real working conditions. By analyzing stress distribution, deformation, and load capacity, we ensure the machine frame achieves maximum strength, precision, and durability before production.

Request A Quote

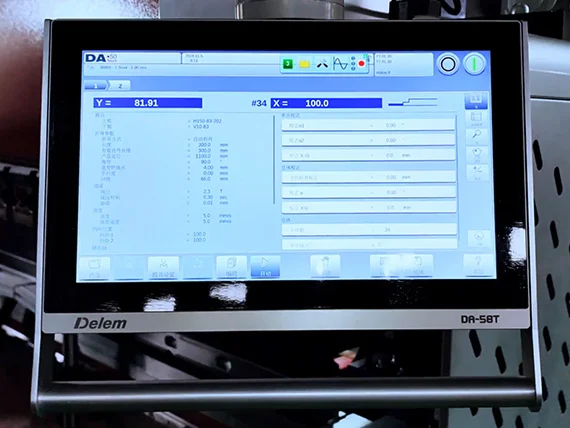

CNC Controller

We provide press brake CNC control systems that can be fully customized, with axis configurations ranging from 4-axis to 6-axis and 8-axis. Every system is customized to meet the unique production needs of the client, whether they are standard bending, complex multi-step operations, or fully automated bending production. Our products are made to be as accurate, effective, and simple to use as possible.

We can suggest the best features, such as 2D and 3D programming and comprehensive 3D simulation capabilities, based on your production demands. We collaborate with well-known CNC manufacturers like Delem, Cybelec, ESA, and STEP to guarantee that your press brake has cutting-edge control technology for dependable operation and exceptional bending precision.

Request A Quote

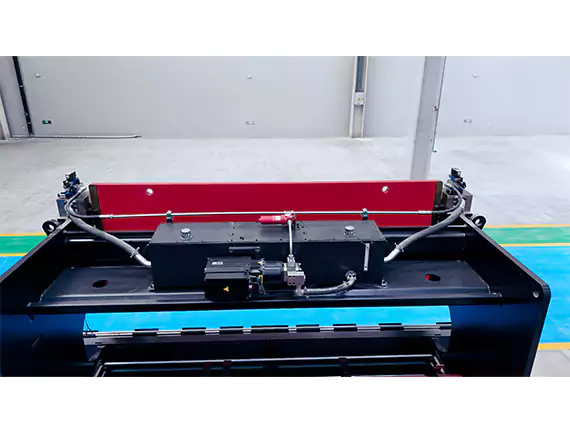

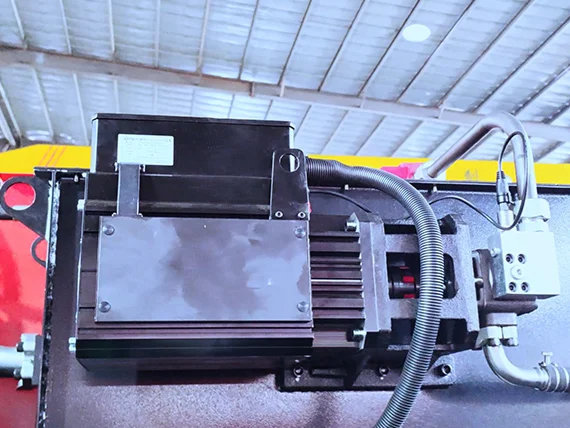

Hydraulic System

Premium parts from Rexroth and Hawe are available for our hydraulic systems, guaranteeing long service life, excellent efficiency, and steady performance. Because of the design's independent oil tank, after-sales maintenance is made simpler and more convenient. The oil tank receives an anti-rust phosphating treatment to increase durability and successfully stop corrosion over time.

Additionally, by preventing the development of sludge that can clog oil pipelines over time, this treatment helps preserve the purity of the oil. With the help of sophisticated hydraulic components, sturdy construction, and proactive strategies, our press brakes provide dependable operation and less downtime to clients all over the world.

Request A Quote

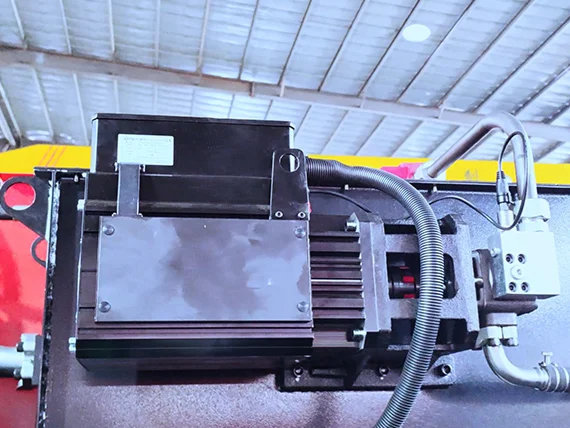

JS Ragos Servo Motor

JS Ragos high-efficiency servo motors that can reduce electric bills by 20–30% compared to conventional Siemens motors. These servo motors operate with remarkably low noise—around 20 dB—providing a quieter, more comfortable working environment. The combination of advanced hydraulics and energy-saving, low-noise servo technology ensures our press brakes deliver both superior performance and reduced operating costs.

Request A Quote

Light Curtain

DSP LASER protects the pressbrake operator from the danger of crushing that can take place accidentally between the moving part of the machine and the fixed one.The project idea used for this device is the one to fit out the moving pert of the pressbrake with a protection zone.

This is a volume of suitable and special dimensions generated by DSP LASER and placed under the upper tool vertex at a higher distance than that the machine requires to stop.So the protection zone, that moves together with the mobile part because integral with it, advances the race of this one towards the fixed pert. An obstacle (for example the Operator fingers) when entering the protection zone. Is detected immediately causing consequently the interruption of the mobile part motion.

Request A Quote

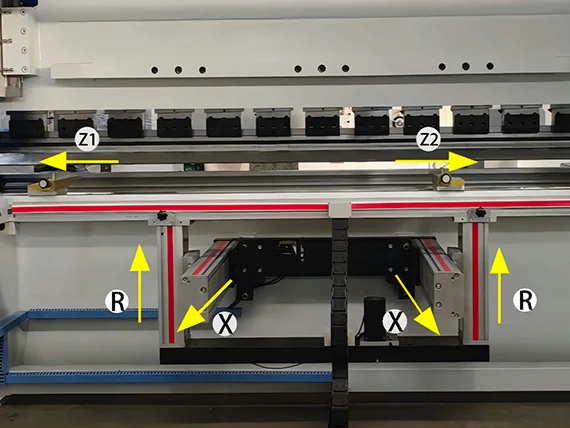

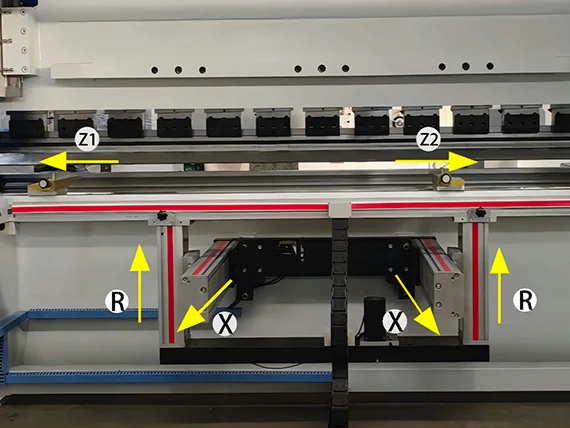

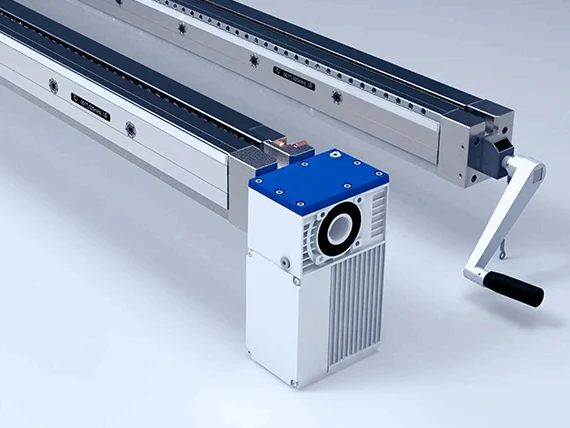

Back Gauge

- Ball screws and linear guide partner TPI, Hiwin

- Optional axes Z1‐Z2.

- Fingers with double stop and micrometric adjustment.

- Position accuracy ± 0.03 mm.

- Z axis speed 1000 mm/s.

- X axis speed 400 mm/s.

- Light curtain on the back side

Request A Quote

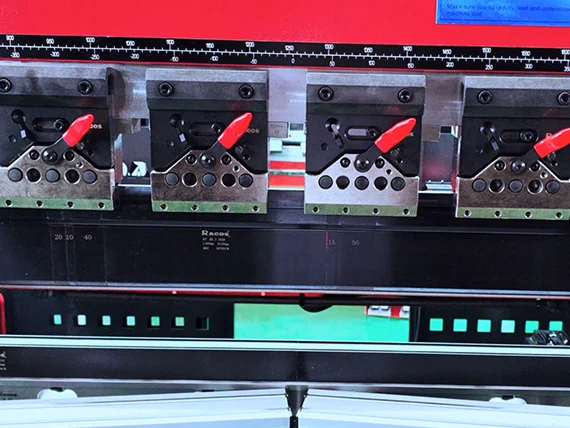

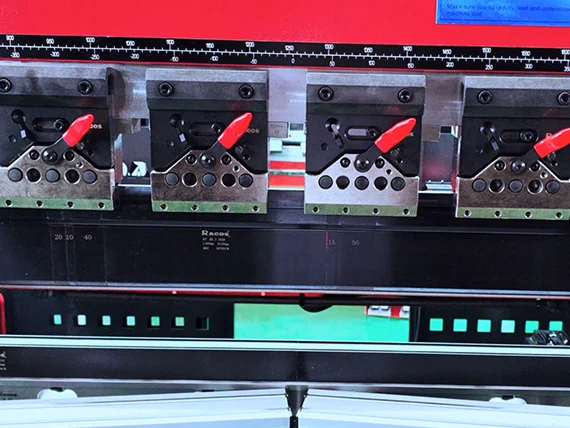

Amada Type Clamp

Upper press brake punches can be installed or removed quickly, safely, and without the need for tools thanks to Amada quick clamps. Operators may secure or release equipment in a matter of seconds with a basic lever or cam-lock mechanism, greatly cutting setup time and increasing production productivity.

Manufactured with high-strength alloy steel and precision-machined for perfect alignment, Amada quick clamps ensure stable clamping force and consistent bending accuracy. Their ergonomic design minimizes operator fatigue, while the durable construction guarantees long service life even under heavy-duty production conditions.

Request A Quote

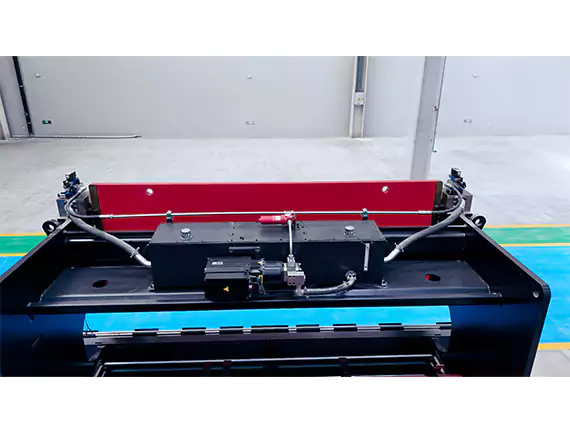

Crowning Table

A crowning table is a press brake feature designed to compensate for deflection in the machine frame during bending.

By using mechanical wedges or a hydraulic system to create a slight upward curve in the center of the table, it ensures consistent bend angles along the entire workpiece length, improving overall bending accuracy.

Request A Quote

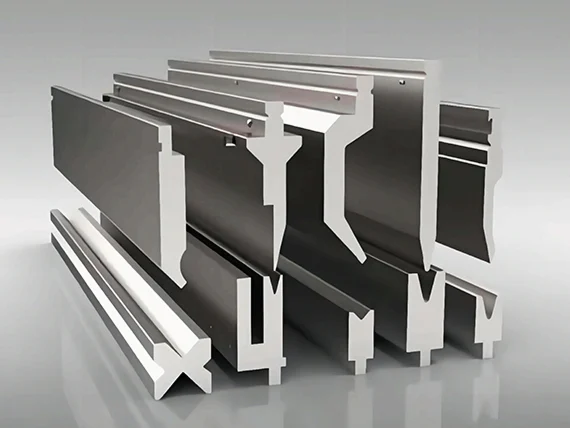

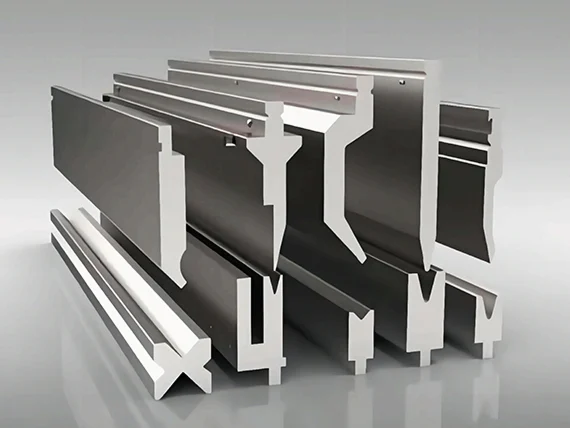

Tooling

All of our machines come standard with one complete set of tooling, ensuring you can begin production immediately after installation.

Request A Quote

Customization Tooling Service

We offer press brake tooling that is specially designed to accommodate a variety of bending applications. Every tool is made from premium 42CrMo alloy steel, which has remarkable strength, durability, and resistance to wear. To increase service life and preserve constant bending quality, each tool is precisely heat-treated.

Additionally, we provide segmentation services, which enable the equipment to be separated into manageable lengths for quicker setup and simpler handling. To give customers the most flexibility for their press brake operations, we can manufacture tooling that is compatible with Wila, Amada, and other key tooling systems.

Request A Quote

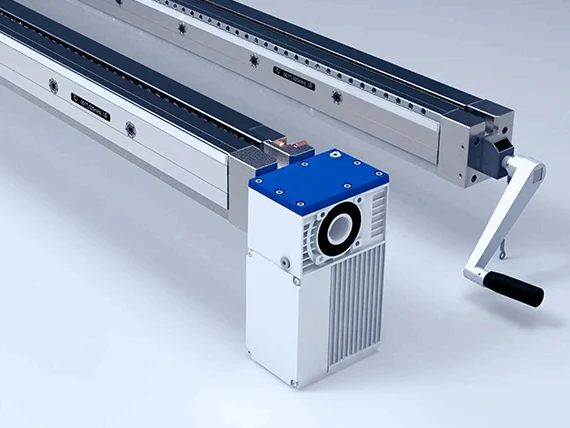

Laser Check Angle Measurement System

The Laser check system, developed with Data-M & Vision Components, ensures highly accurate bend angles after just a single bending operation.a

As a fully automatic, laser-assisted bend angle measurement solution for CNC press brakes, iMeasure delivers precise angle detection regardless of material type or thickness. With an accuracy exceeding ±0.1°, it achieves a level of precision previously unattainable.a

The system automatically corrects bending angles by projecting a laser beam onto the sheet surface, which is then detected by a camera. By calculating the angle between the laser beam and the camera axis, the system determines the actual bend angle, compensates for springback, and optimizes the applied force for perfect results.a

Request A Quote

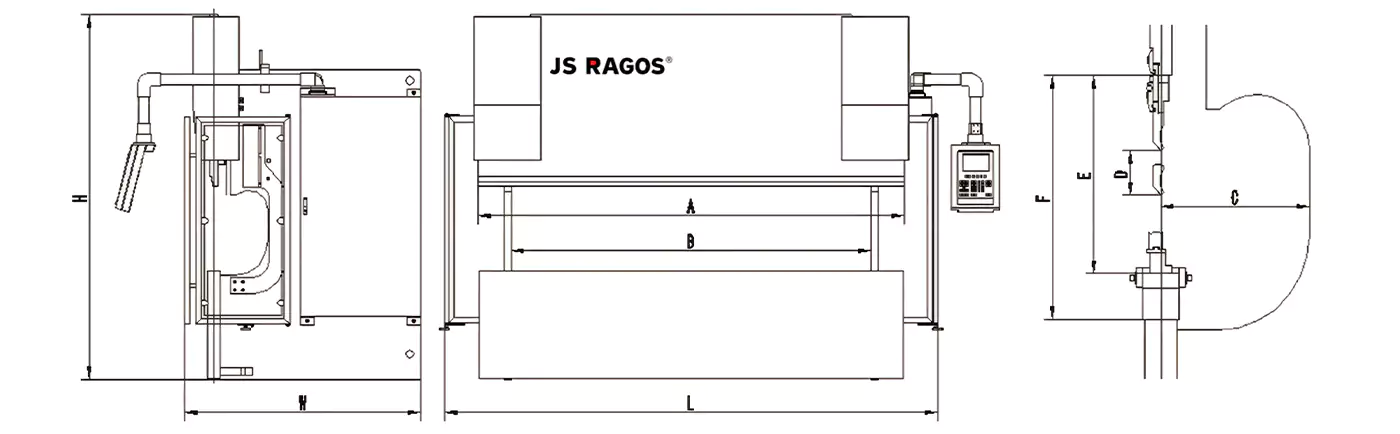

Technical Specifications

For more detailed specifications, please don't hesitate to contact us. For more detailed specifications, please don't hesitate to contact us. For more detailed specifications, please don't hesitate to contact us.

| Speed | Tonnage

(ton) |

Length

(mm) |

Distance between sides

(mm) |

Throat(mm) | Stroke

(mm) |

Daylight

(mm) |

Power(kw) | Speed(mm/s) | Dimension(mm) | Weight

(kg) |

||||

| Fast | Apporach | return | Length | Width | Height | |||||||||

| HG-35-1200 | 35 | 1200 | 1000 | 300 | 160 | 450 | 4 | 200 | 10 | 180 | 1800 | 1255 | 2400 | 3000 |

| HG-50-1600 | 50 | 1600 | 1260 | 300 | 160 | 450 | 5.5 | 200 | 10 | 180 | 2100 | 1355 | 2400 | 4000 |

| HG-60-2000 | 60 | 2000 | 1600 | 400 | 160 | 450 | 7.5 | 200 | 10 | 180 | 2235+415 | 1600 | 2370 | 4500 |

| HG-80-2500 | 80 | 2500 | 2000 | 400 | 200 | 450 | 7.5 | 200 | 10 | 180 | 2680+370 | 1930 | 2500 | 5500 |

| HG-110-2500 | 110 | 2500 | 2000 | 400 | 200 | 500 | 8.8 | 200 | 10 | 160 | 2690+380 | 1930 | 2540 | 6500 |

| HG-110-3200 | 3200 | 2700 | 3390+380 | 2010 | 2540 | 7150 | ||||||||

| HG-110-4000 | 4000 | 3500 | 4190+380 | 2010 | 2585 | 8250 | ||||||||

| HG-130-2500 | 130 | 2500 | 2000 | 400 | 200 | 500 | 10.2 | 200 | 10 | 160 | 2690+380 | 2020 | 2540 | 6600 |

| HG-130-3200 | 3200 | 2700 | 3390+380 | 2540 | 7550 | |||||||||

| HG-130-4000 | 4000 | 3500 | 4190+380 | 2595 | 8550 | |||||||||

| HG-130-5000 | 5000 | 4100 | 4990+380 | 2695 | 13000 | |||||||||

| HG-170-3200 | 170 | 3200 | 2700 | 400 | 200 | 500 | 10.2 | 180 | 10 | 150 | 3400+390 | 2025 | 2720 | 8650 |

| HG-170-4000 | 4000 | 3500 | 4200+390 | 2720 | 10500 | |||||||||

| HG-170-5000 | 5000 | 4100 | 5000+390 | 2820 | 15000 | |||||||||

| HG-170-6000 | 6000 | 5000 | 5900+390 | 2870 | 17000 | |||||||||

| HG-220-3200 | 220 | 3200 | 2700 | 400 | 200 | 500 | 15.2 | 160 | 10 | 140 | 3410+400 | 2120 | 2780 | 11000 |

| HG-220-4000 | 4000 | 3500 | 4210+400 | 2780 | 12200 | |||||||||

| HG-220-5000 | 5000 | 4100 | 5010+400 | 2880 | 18000 | |||||||||

| HG-220-6000 | 6000 | 5000 | 5910+400 | 2980 | 22000 | |||||||||

| HG-250-3200 | 250 | 3200 | 2700 | 400 | 250 | 550 | 15.2 | 150 | 9 | 130 | 3420+435 | 2180 | 3060 | 13400 |

| HG-250-4000 | 4000 | 3500 | 4220+435 | 2185 | 3060 | 15800 | ||||||||

| HG-250-5000 | 5000 | 4100 | 5020+390 | 2200 | 3300 | 20000 | ||||||||

| HG-250-6000 | 6000 | 5000 | 5980+430 | 2240 | 3400 | 26000 | ||||||||

| HG-320-3200 | 320 | 3200 | 2700 | 400 | 300 | 600 | 18.5 | 130 | 9 | 110 | 3450+405 | 2400 | 3215 | 15700 |

| HG-320-4000 | 4000 | 3500 | 4250+405 | 2400 | 3265 | 18000 | ||||||||

| HG-320-5000 | 5000 | 4100 | 5060+390 | 2450 | 3565 | 20000 | ||||||||

| HG-320-6000 | 6000 | 5000 | 5980+430 | 2470 | 3800 | 28500 | ||||||||

| HG-400-3200 | 400 | 3200 | 2700 | 450 | 300 | 600 | 30 | 110 | 7 | 90 | 3800 | 2400 | 3500 | 21000 |

| HG-400-4000 | 4000 | 3500 | 4600 | 3700 | 23000 | |||||||||

| HG-400-5000 | 5000 | 4100 | 5600 | 3950 | 25900 | |||||||||

| HG-400-6000 | 6000 | 5000 | 6600 | 4200 | 31500 | |||||||||

Upgrade Solutions

If you need to purchase separate accessories or services to renovate the machine, you can learn more through the link below.

CNC Control System

Back Gauge Modifcation

Safety Options(NR 12)

Crowning System

Tooling Clamping System

Bending Follower

Hybrid DSVP System

Bending Off-line Software

Angle Measurement Device

Frequently Asked Questions

-

What Is Finite Element Analysis (Fea), And Why Is It Important In Press Brake Design?

-

Can I Customize The CNC Control System? Cnc

-

Which Hydraulic Components Are Used?

-

How Does The DSP Laser Safety Light Curtain Protect Operators? DSP

-

What Is An Amada-Type Quick Clamp, And Why Use It?

-

What Is The Laser Check Angle Measurement System?

-

What Tooling Is Included With The Machine?

-

Can You Provide Customized Press Brake Tooling?