Up Acting Press Brake

JS Ragos up-acting press brake operates with the lower beam (bed) moving upward toward a fixed upper beam. This design is less common but still offers unique benefits for certain applications. Combined with the fast cycle speed of up to 55 strokes per minute, it delivers both accuracy and high productivity. Main Features: 1.Compact Design oSince the upper beam remains fixed, the structure can be more compact. oOften used for smaller press brakes or specific niche applications. 2.Operator-Friendly Setup oThe workpiece can remain supported while the lower beam moves upward. oEasier for handling lightweight or shorter parts. 3.Simplified Hydraulics oTypically uses a single upward hydraulic movement. oCan reduce complexity in some machine designs. 4.Lower Initial Cost oUp-acting systems may be less expensive to build in smaller tonnage ranges. oAttractive for entry-level sheet metal operations.

-

Model MG-1003

-

Nominal Pressure 100Ton

-

Bending Length Bending length

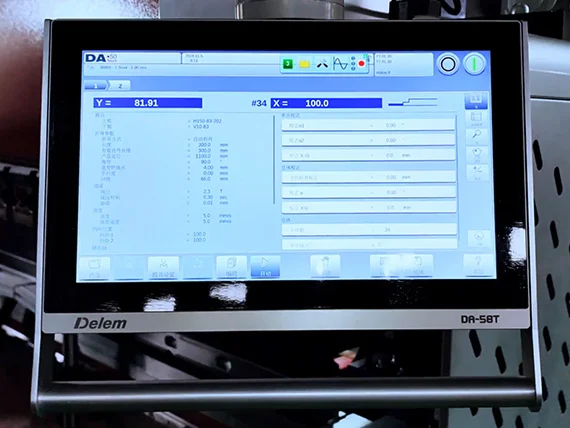

Controller

JS RAGOS self-developed CNC control systems

Designed for simplicity, reliability, and ease of use – even for operators with little to no experience.

Intuitive and Versatile Interface

The system features a multi-mode, user-friendly control panel that minimizes learning time and enables quick operation setup. Its straightforward design ensures even inexperienced operators c

JS RAGOS self-developed CNC control systems

Designed for simplicity, reliability, and ease of use – even for operators with little to no experience.

Intuitive and Versatile Interface

The system features a multi-mode, user-friendly control panel that minimizes learning time and enables quick operation setup. Its straightforward design ensures even inexperienced operators can achieve smooth and accurate bending.

smooth and accurate bending.

Request A Quote

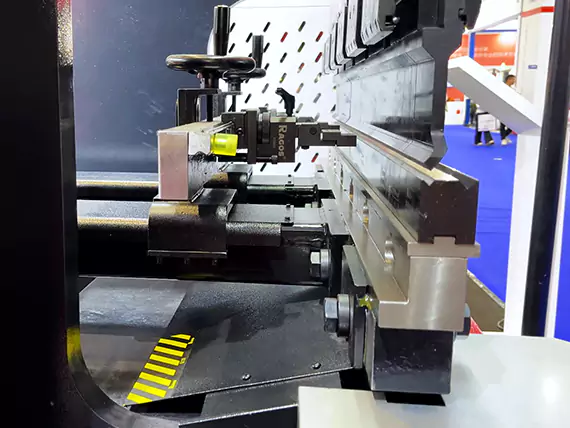

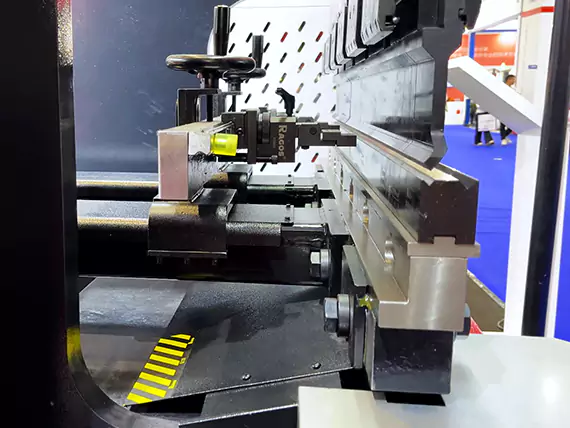

Amada Scrip type punch holder

Tool-Free Locking: To firmly clamp it, just slip in the punch and turn the lever; no tool is needed.

Time Savings: Compared to standard holders, tool changeover times are cut by more than 50%, greatly reducing setup time and labor.

Versatile Clamping:

Works with both front and rear clamp plates, allowing flexibility in punch placement to accommodate interference or intricate part geometries.

Request A Quote

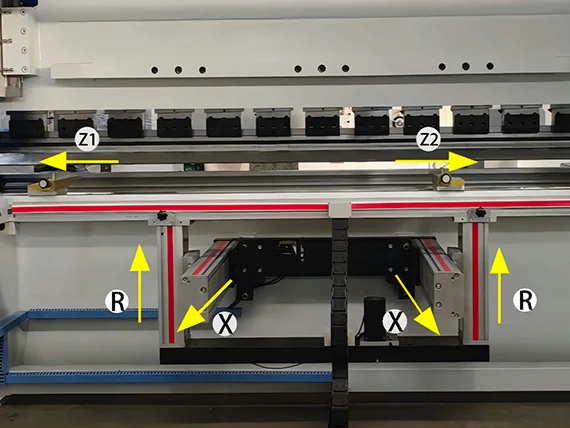

Reliable Backgauge

The backgauge system in an up-acting press brake is designed to ensure accurate and repeatable positioning of the workpiece during bending. It provides precise alignment, reducing setup time and improving bending consistency.

- High Accuracy– Controlled by CNC for reliable and consistent positioning.

- Flexible Adjustment– Can be programmed to move along multiple axes, allowing for complex bending sequences.

- Stability– The up-acting design ensures the workpiece remains firmly supported on the table, making backgauge positioning more stable.

Request A Quote

Technical Specifications

For more detailed specifications, please don't hesitate to contact us. For more detailed specifications, please don't hesitate to contact us. For more detailed specifications, please don't hesitate to contact us!

| Model | MG-1003 | MG-8025 | MG-6020 | MG-5016 | MG-3512 | |

| Nominal pressure | 100ton | 80ton | 60ton | 50ton | 35ton | |

| Bending length | 3100mm | 2500mm | 2000mm | 1600mm | 1200mm | |

| Distance between side plates | 2550mm | 2090mm | 1700mm | 1220mm | 1020mm | |

| Throat depth | 405mm | 405mm | 405mm | 405mm | 300mm | |

| Opening height | 390mm | 390mm | 390mm | 390mm | 390mm | |

| Stroke | 100mm | 100mm | 100mm | 100mm | 100mm | |

| Working speed | Fast speed | 52mm/s | 52mm/s | 52mm/s | 52mm/s | 52mm/s |

| Bending speed | 10mm/s | 10mm/s | 10mm/s | 10mm/s | 10mm/s | |

| Return speed | 46mm/s | 46mm/s | 46mm/s | 46mm/s | 46mm/s | |

| Dimension | Length | 3130mm | 2650mm | 2180mm | 1680mm | 1465mm |

| Width | 1450mm | 1350mm | 1350mm | 1350mm | 1200mm | |

| Height | 2480mm | 2320mm | 2160mm | 2160mm | 1960mm | |

| Main motor power | 7.5KW | 7.5KW | 5.5KW | 4.0KW | 3.0KW | |

| Number of oil cylinders | 3pc | 3pc | 3pc | 1pc | 1pc | |

| Capacity of oil tanks | 72L | 55L | 45L | 40L | 33L | |

| Weight | 6600kg | 4300kg | 3500kg | 2800kg | 2200kg | |

Upgrade Solutions

If you need to purchase separate accessories or services to renovate the machine, you can learn more through the link below.

CNC Control System

Back Gauge Modifcation

Safety Options(NR 12)

Crowning System

Tooling Clamping System

Bending Follower

Hybrid DSVP System

Bending Off-line Software

Angle Measurement Device

Frequently Asked Questions

-

What is the structural difference between an up acting press brake and a down acting model?

-

Why is an up acting press brake preferred in limited space environments?

-

Does an up acting design affect bending accuracy or repeatability?

-

What kind of materials and thicknesses are suitable for up acting press brakes?

-

Are safety systems different in up acting machines compared to down acting types?