MSD

- ♦️Laser protection,Single beam

- ♦️The safety level is CAT.4 and SIL3

- ♦️Detection Case protection degree: IP 65

- ♦️Laser classification: class 1 M

- ♦️Response time: 5 ms

- ♦️Operating temperature 0°C 50°C

- ♦️Mounted on the lower tool

- ♦️Change Speed Point : 5mm + Stopping Space

- ♦️The maximum protective distance is up to 15M

- ♦️LED indicators show various states

Safety Devices-DSP

DSP LASER protects the pressbrake operator from the danger of crushing that can take place accidentally between the moving part of the machine and the fixed one.The project idea used for this device is the one to fit out the moving pert of the pressbrake with a protection zone.

This is a volume of suitable and special dimensions generated by DSP LASER and placed under the upper tool vertex at a higher distance than that the machine requires to stop.So the protection zone, that moves together with the mobile part because integral with it, advances the race of this one towards the fixed pert. An obstacle (for example the Operator fingers) when entering the protection zone. Is detected immediately causing consequently the interruption of the mobile part motion.

- -Laser protection, Multi beam Receiver

- -Pretective areas, Front, center and rear.

- -The safety level is CAT.4 and SIL3

- - Detection Case protection degree: IP 65

- -Laser classification: class 1 M

- - Response time: 5 ms

- -Operating temperature 0°C 50°C

- -Mounted on the upper beam

- -Change Speed Point : 5mm + Stopping Space

- -The maximum protective distance is up to 15M

- -LED indicators show various states

DSP AP

The safety device DSP LASER AP is a visible laser emission barrier which, realized and placed as described in Standard EN12622, protects the operator of the press brake against the danger to be squashed between the upper tool and the lower tool during the closing of the press in high speed. The device is constituted by a transmitter TX, which generates the laser emission, and by a receiver RX, which receives it and transmits the processing of the received signals to MCS module.

MCS module monitors and manages even other machine systems and components.

- -Laser protection, Multi beam Receiver

- -Pretective areas, Front, center and rear.

- -The safety level is CAT.4 and SIL3

- - Detection Case protection degree: IP 65

- -Laser classification: class 1 M

- - Response time: 5 ms

- -Operating temperature 0°C 50°C

- -Mounted on the upper beam

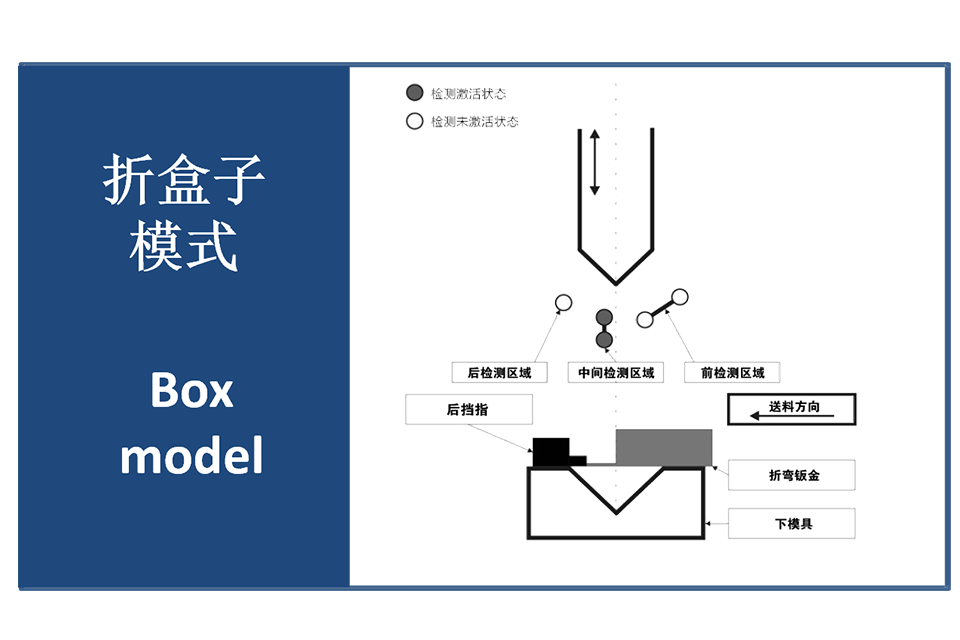

- -Box Mode Function

- -Overrun Distance Test (automatic)

- -High Speed Control

- -Low Speed Control

- -Automuting in Low Speed

- -Direction Control

- -Change Speed Point: 2mm

- -Up to 2 Pedals Control with Antipanic

- -Side Repairs Control

- -Back Repair Control

- -Back Gauge driving

- -Automatic tools block

- -Emergency Control

- -Valve direct driving

- -Valve Monitoring

- -CNC interface

- -Hemming Control

- -8 pulsed safety outputs

- -8 pulsed safety inputs

- -24 safety inputs

- -8 safety outputs

- (maximum current up to 3.2A)

- -12 general inputs

- -14 general outputs

- -3 special function outputs

- -2 linear encoders inputs(Y1/Y2)

- -1 RS232 communication interface

Safety Devices-DSP AP EX+MCS EX

- -Laser Protection (F+C+R)

- - Box Mode Function

- - Very Low Muting Point (~2mm)

- - Automatic Overrun Distance Test

- - High Speed Control

- - Low Speed Control

- - Automuting in Safety Condition

- - Direction Control

- - Up to 2 Pedals Control with Antipanic

- - Side Repair Control

- - Back Repair Control

- - Back Gauge Safety Stop

- - No Clamping Tools Control

- - Emergency Control

- - N.4 Valves Direct Driving (up to 3,2A for

- each output)

- - Valve Monitoring

- - CNC interface

- - No Hemming Control

- - RS232 Communication

- - Robot Mode

- - NO CE Certification

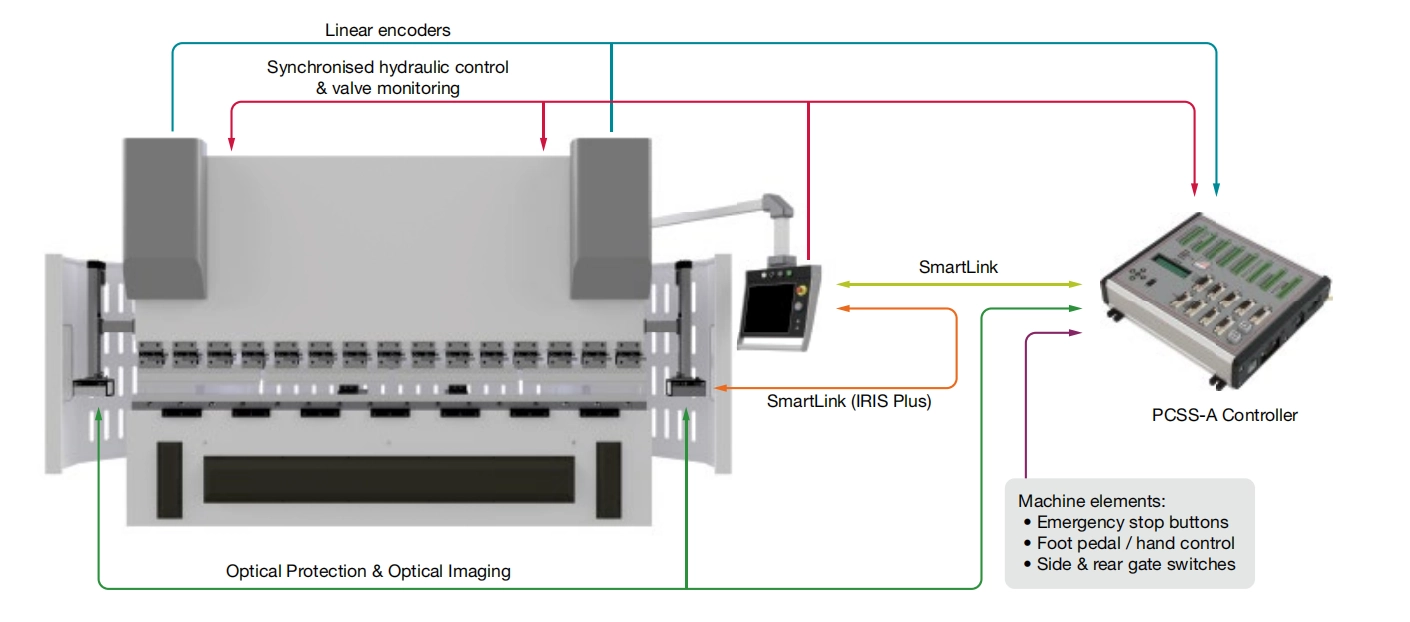

IRIS Laser Safe

- PCSS-A Standard features

- Streamlined management of machine safety elements including valve control, valve monitoring, foot pedals, hand controls, emergency stop, side and rear gate switches, level switches, etc.

- Optical protection system management, control, muting and monitoring.

- Dual optical protection support. Lazer Safe optical protection and third party light curtains can be installed on the same machine.

- Connects to Y1 / Y2 linear encoders for automatic speed and performance monitoring stopping

- Fully embedded communication software interface with the CNC system. Compatible with Delem, Cybelec and ESA. Custom CNC integration also supported.

- CE Certified hardware and software.

Press Brake design streamlined with PCSS-A + Optical Protection & Imaging

This provides an efficient and cost effective platform with fewer components, reduced wiring, simplified interface and CE Certified hardware and software to minimize engineering and build time.

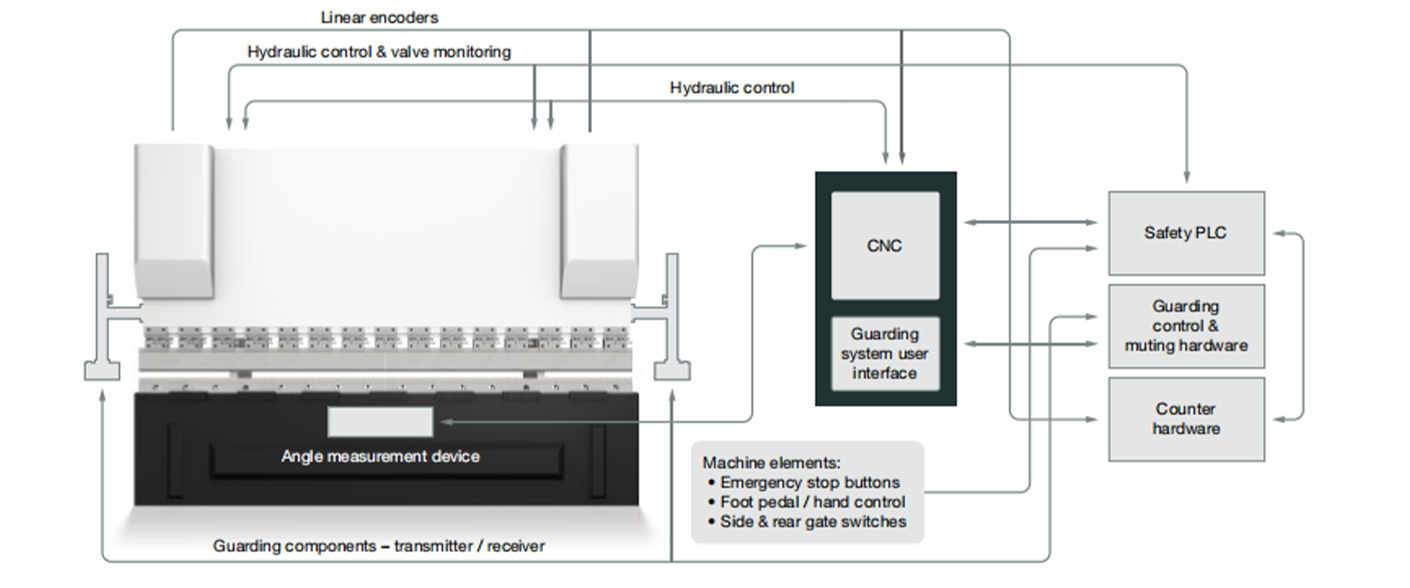

Press Brake designed with third party components

Traditional press brake design increases the level of complexity and requires many third party components to be made to work together leading to hardware and software compatibility issues, adds extra wiring and increased cabinet size. The manufacturer must consider CE Certification in design and integration when using third party hardware components plus develop and certify the control software. This inefficient design leads to longer manufacturing time and increased build cost.

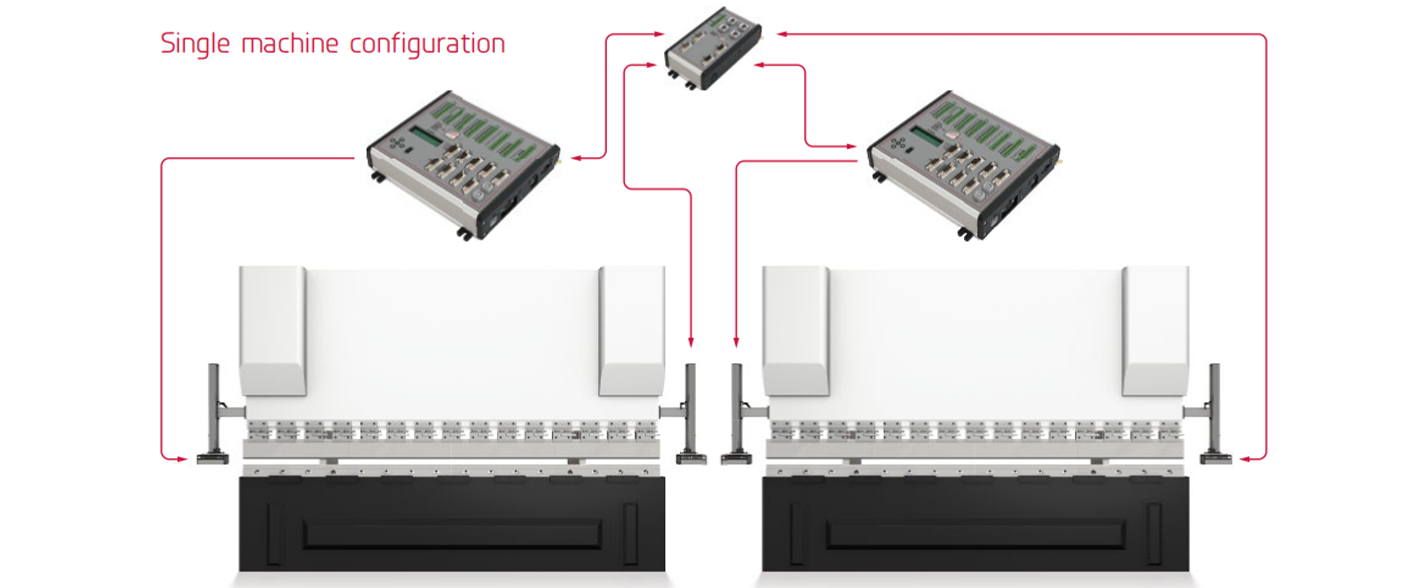

Solution for tandem press brakes

The PCSS–A embedded safety controller range expands the possibilities for machine control with the next generation solution for tandem press brakes. The latest tandem solution comprises a Tandem Adaptor that synchronises safety functions and control across both machines and a dedicated optical system for flexible guarding in both single and tandem configurations.

Wireless Foot Pedal

The wireless foot pedal solution is the new expansion option for the PCSS–A1 or PCSS–A2 platform that makes it simple to incorporate wireless functionality by integrating the wireless module into your existing foot pedal or by designing a new pedal from the ground up. The wireless system uses a safe, dual–channel SIL 3 communications method with two–way communication between the press brake and the foot pedal while also providing dynamic range and position monitoring through the

use of ultrasonic sensors.

- 1. WRM

- 2. Reset Button

- 3. Up Button

- 4. Ultrasonic Sensors

- 5. Solar Panel

- 6. Display

- 7. E-Stop

- 8. Station Active LED

- 9. Battery Charge / Status

- 10. Wireless Comms Status

- 11. WRM Status

- 12. OEM Defined WRM ID

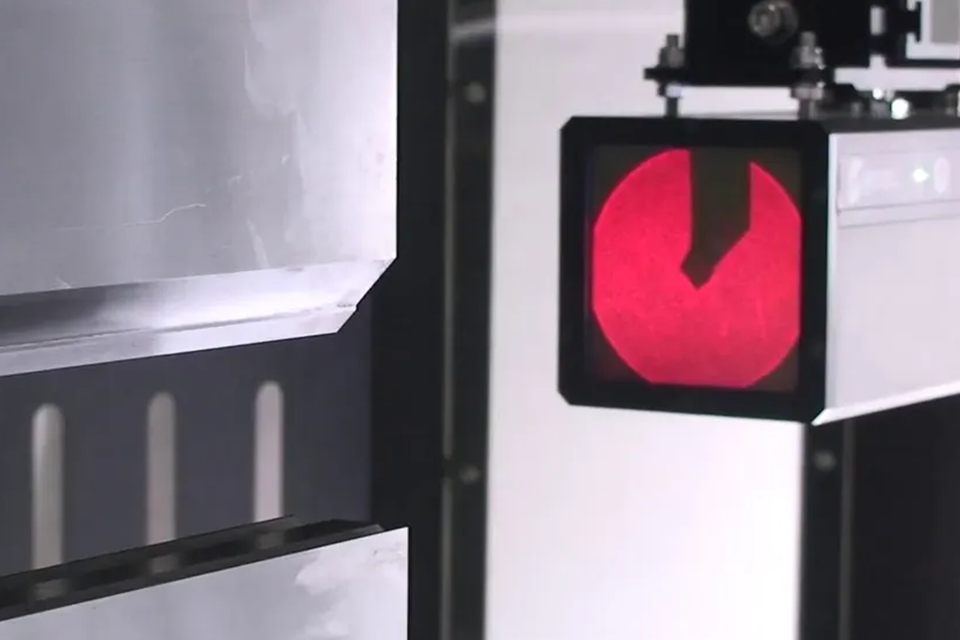

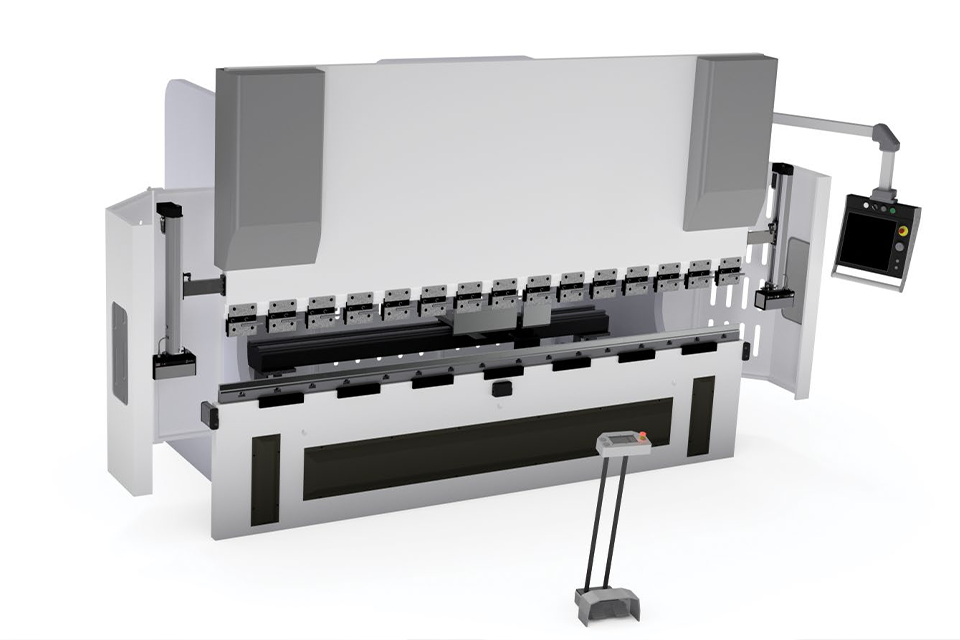

Optical protection

Our premium range of optical protection systems provide press brake manufacturers with the optimal solution for superior operator protection combined with the highest possible level of machine productivity and performance.

Optical protection systems comprise a laser transmitter and receiver that are mounted to the upper beam of the press brake. A continuous laser field protects the zone directly below and around the punch tip allowing the operator to hold the work piece as the tools close at high speed. If an obstruction is detected the machine is automatically stopped.

This close proximity protection allows the operator unrestricted access to the point of operation for increased productivity and unlike traditional light curtains, reduces fatigue by enabling the operator to remain standing in the same position.

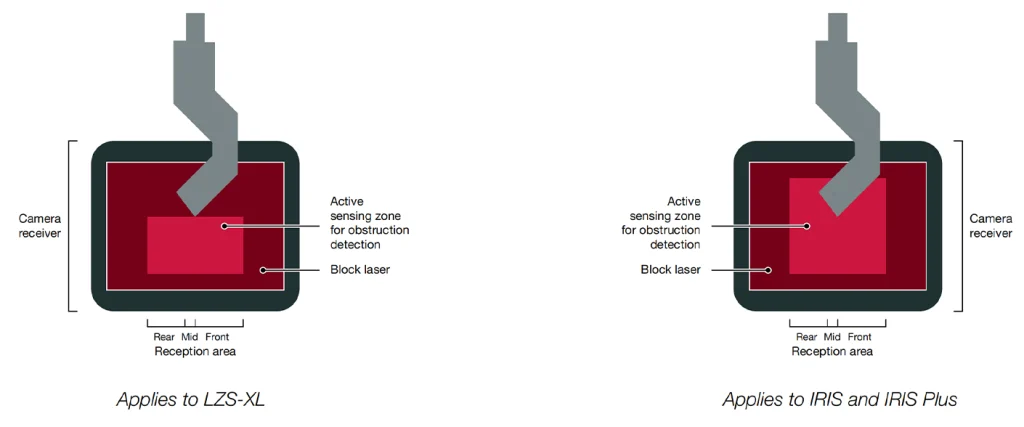

The laser field is processed by the receiver and divided into three continuous zones to detect obstructions entering from the front, sides and rear of the tool area.

The front zone provides protection forward of the tool while the middle zone protects the area just behind the tip of the punch. The rear zone provides additional protection for the open gaps created when segmented tooling is used. The protective zones are independently and automatically muted to suit different shaped work pieces allowing parts to be formed safely at high speed to achieve maximum productivity.